in real-time during machining

(Cutting version) i-flash Cutting Vibration Measurement Type

Diagnostic Device for Machining Phenomena

Diagnostic holder of processing phenomena

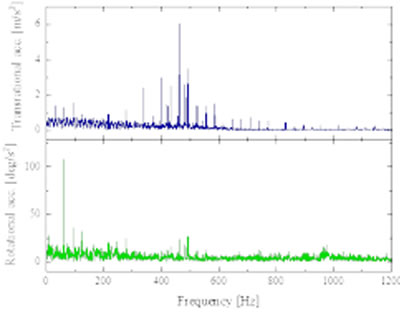

Frequency analysis is possible through high-speed sampling of acceleration data.

High-speed data collection reads the true waveform and supports the selection of optimal machining conditions.

*Supported only for Machinability Evaluation Test Service and Rental Service

in real-time during machining

controller, and wireless transceiver

built into the tool holder

display and recording software

This device enables real-time monitoring of vibration during cutting.

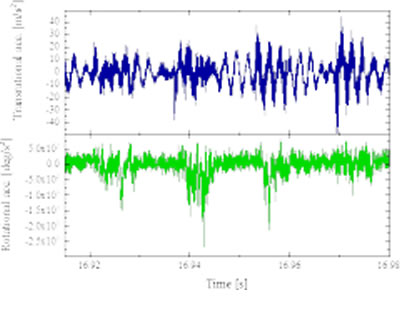

Frequency analysis is possible through high-speed sampling of acceleration data. (Sampling rate 44.1kHz)

*Supported only for Machinability Evaluation Test Service and Rental Service

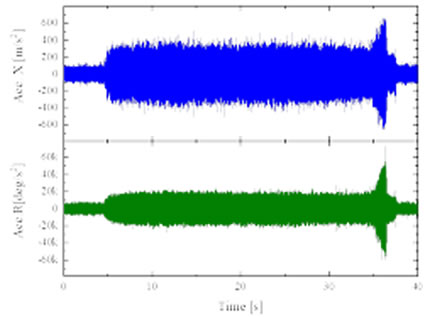

High-speed data collection of acceleration reads the true waveform, enabling the selection of optimal machining conditions to prevent chatter during machining.

The realization of a high sampling rate makes it possible to monitor the acceleration of each cutting edge, even during high-speed rotation.

Realizing the “visualization” of machining phenomena,

it supports the IoT of cutting, optimal machining condition selection, and trouble analysis.

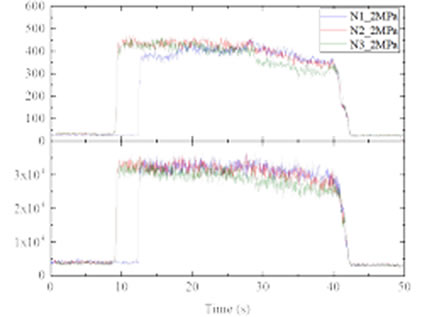

[Examples of High-Speed Acceleration Sample Data Usage]

・Elucidation of chatter vibration phenomena

・Evaluation of developed tools

・Machine tool spindle evaluation

(Cutting version) Simultaneous Heat and Vibration Measurement Type

(Cutting version) i-flash Cutting Vibration Measurement Type

Rental ServiceRental

We solve these kinds of problems

I want to know better conditions

than the current machining conditions

I want to know the machinability of new tools

I want to know the machinability of new materials

I want to know the performance of new cutting fluids

MULTI INTELLIGENCE® is also available for rent.

If you are wondering what it can do, please check the performance of MULTI INTELLIGENCE® through our rental service.

- ● The items for rent are those shown in the photo below. *Please prepare your own PC.

- ● Available for rent starting from 1 week.

- ● MULTI INTELLIGENCE® can also be utilized for outsourced testing.

Rental Equipment

- Designated Holder

- Transceiver

- Software Dongle Key (USB)

- Dedicated Charger

*Please prepare your own PC

Basic SpecificationsSpecification

Tool Holder

| Shank Standard | BT30,BT40,BT50,HSK63A,100A *Other than basic specifications can be accommodated (consultation required) |

|---|---|

| Chuck Type | See diagram below *1 We also accept consultations regarding standards other than those in the compatibility table |

| Maximum Tool Insertion Depth | 39mm |

| Maximum Spindle Speed |

BT30,BT40,HSK63A:20,000rpm BT50,HSK100A:10,000rpm |

| Rotation Balance | 1.2g・mm or less |

| Other | Rechargeable, External Coolant |

*1 Compatibility Table

ER: Taper Collet, 16° taper compliant with standard DIN6499/ISO15488

ER: Taper Collet, 16° taper compliant with standard DIN6499/ISO15488

SL: Side Lock

FM: Face Mill Arbor

Battery

| Power Source | 3.7V Lithium-ion secondary battery (Built into tool holder) |

|---|---|

| Continuous Usage Time | Approx. 2h |

| Charging Time | Max Approx. 2.5H |

Wireless

| Wireless Transmission Sampling Rate | 44.1 kHz |

|---|---|

| Operating Radio Frequency Band | 2.4GHz band |

| Communication Range | Approx. 10m (without obstructions) |

Acceleration Sensor

| Acceleration Detection Direction (2 modes are switchable) |

Rotational/Translational Mode: Perpendicular to rotation axis [X], Rotational direction [R] Orthogonal 2-Direction Mode: Perpendicular to rotation axis [X], [Y] |

|---|---|

| Input Range | [X],[Y] direction : 818 m/s2 [R] direction : 163,600 rad/s2 |

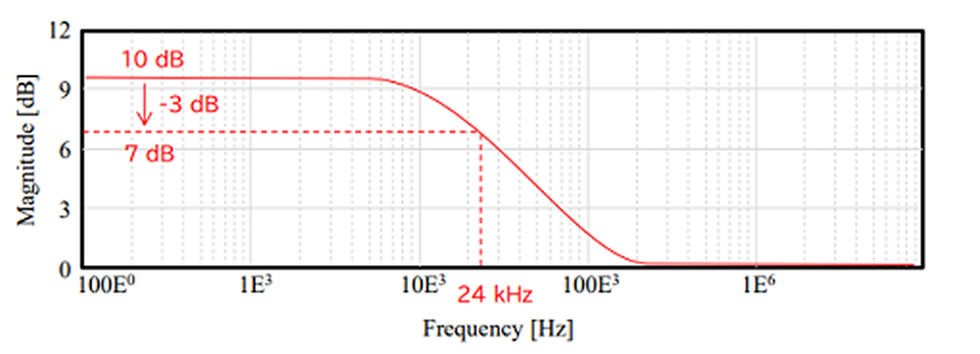

| Filter Characteristics | Low-pass filter 24 kHz (*2 Frequency characteristic diagram attached) |

*2 Frequency Characteristic Diagram

Product LineupLINEUP

MULTI INTELLIGENCE®

(Cutting version)

Simultaneous Heat and Vibration Measurement Type

This device enables real-time monitoring of tool temperature and vibration during cutting. Temperature measurement while applying coolant is also possible (inner-through possible). Vibration measurement is possible simply by holding the tool.

MULTI INTELLIGENCE®

(Cutting version)

i-flash Cutting Vibration Measurement Type

Frequency analysis is possible through high-speed sampling of acceleration data. (Sampling rate 44.1kHz)

High-speed data collection reads the true waveform and supports the selection of optimal machining conditions.

*Supported only for Machinability Evaluation Test Service and Rental Service

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will hold a meeting through a visit or a web conferencing system.

It is also possible to observe in advance what kind of monitoring device MULTI INTELLIGENCE® is.

- Machinability Evaluation Test Service is also available

- You can also request an evaluation utilizing MULTI INTELLIGENCE® through the Machinability Evaluation Test Service.

We support the selection of optimal machining conditions through the “visualization” of machining phenomena.

- TOP

- Product Information

- MULTI INTELLIGENCE®

- (Cutting version) i-flash Cutting Vibration Measurement Type