Patent Acquired Patent No. 7079904

Coolant Management is Extremely Important

-However, on-site management is troublesome and tends to be neglected-Problems related to coolant (spoilage, odor, foaming, rough skin, contamination, discoloration, etc.) are diverse.

If these problems occur, the effectiveness of the coolant (lubricity, cooling performance, etc.) will not be fully realized,

leading to quality issues in cutting and turning.

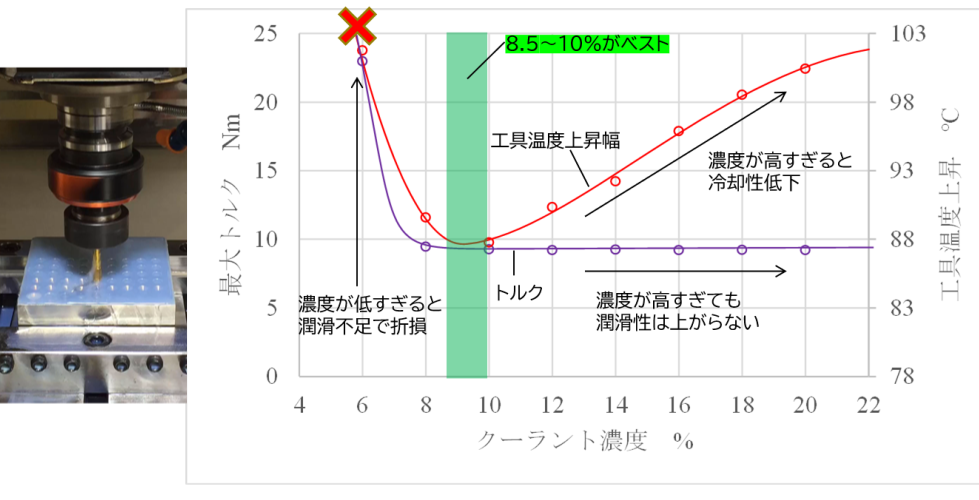

As shown in the data above, when the coolant concentration is between 8.5 and 10%, the rise in tool temperature and torque is suppressed, maximizing the coolant’s effect.

Thus, coolant concentration is extremely important in machining.

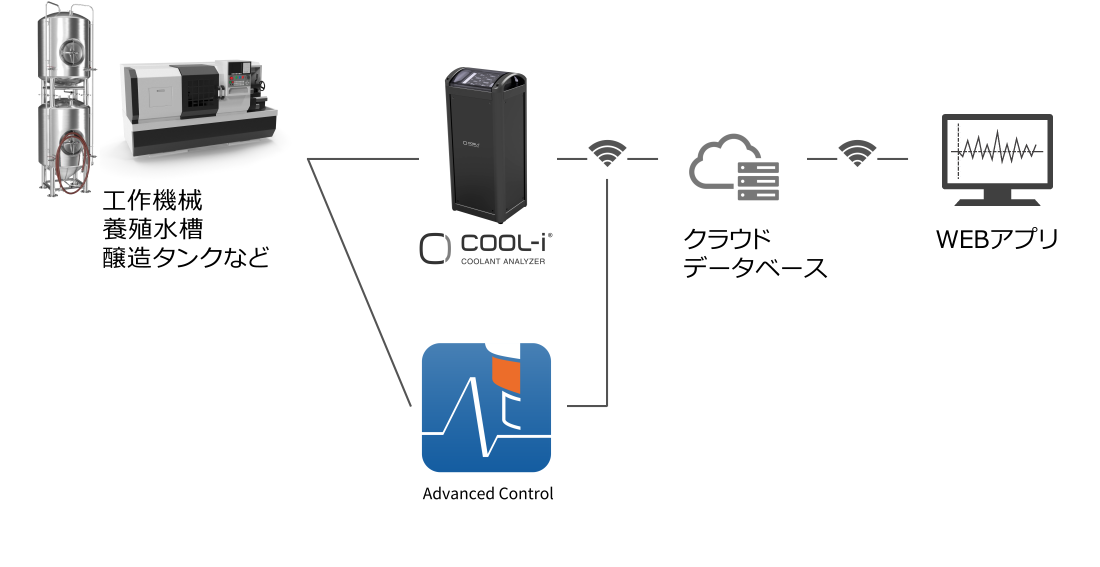

By using COOL-i, monitoring for the purpose of managing coolant concentration, temperature, and pH is possible.

Automatic sampling is performed from the coolant tank, and management can be done on a PC or the cloud.

The obtained data supports your company’s coolant management.

COOL-i® is available for purchase or rental.

COOL-i®

OverviewCase

COOL-i® is a coolant management system that constantly and simultaneously measures the temperature, concentration, pH, and contamination level of water and water-soluble coolants (cutting oil).

Installation is easy: just insert the hose into the tank. It runs on a household 100V power supply.

The liquid is circulated inside the device, constantly and automatically measuring and storing data for the five items mentioned above. It can take over the troublesome management of coolant liquid entirely.

Main FeaturesFeatures

01Easy Installation

Simple setup, just install next to the tank.

02Circulation Method

The drawn-in liquid is

returned to the tank and circulated after sensing.

03Remote Monitoring

Data can be confirmed remotely from a web application

Basic SpecificationsSpecification

Device and System Specifications

| Dimensions | 250×190×560[mm] |

|---|---|

| Mass | Approx. 10[kg] |

| Power Supply | AC100V |

| USB Port | 1 port |

| LAN Port | 1 port |

| Wireless | Wi-Fi available |

| Recording Frequency | 1, 5, 10[min] (Selectable) |

| Data Transmission Method | Wired LAN, Wi-Fi (Selectable) |

| Data Server | Cloud, On-premise (Selectable) |

| WEB App Functions | Time-series data display, Alert function |

Measurement-Related

| Measurement Items Standard Function |

Brix, Contamination Level, Liquid Temperature, Room Temperature, pH |

|---|---|

| Measurement Items Option |

Oxidation-Reduction Potential (ORP) |

| Measurement Range (Resolution) Brix (Concentration) |

0~30(0.1)[%] |

| Measurement Range (Resolution) Contamination Level |

0~100(1) |

| Measurement Range (Resolution) Liquid Temperature・Room Temperature |

5~50(0.1)[°C] |

| Measurement Range (Resolution) pH |

0~14(0.1) |

| Measurement Accuracy Brix (Concentration) |

±0.5[%] |

| Measurement Accuracy Liquid Temperature・Room Temperature |

±0.1[°C] |

| Measurement Accuracy pH |

±0.2 |

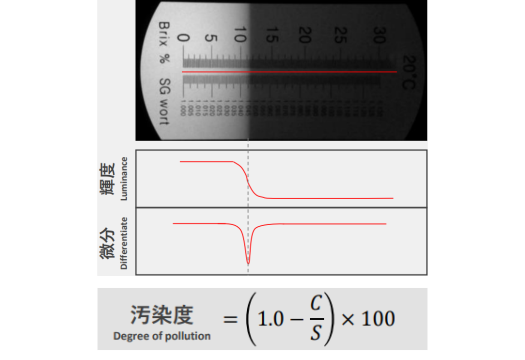

Brix (Concentration) / Contamination Level Evaluation MethodEvalution Brix and pollution

Evaluation Method

① Extract brightness profile of an arbitrary line

② Differentiate the brightness profile

③ Read the pixel position of the differential minimum value (Brix)

④ Normalize the current position (C) based on the differential minimum value (S) of new fluid

(Refer to the figure on the right)

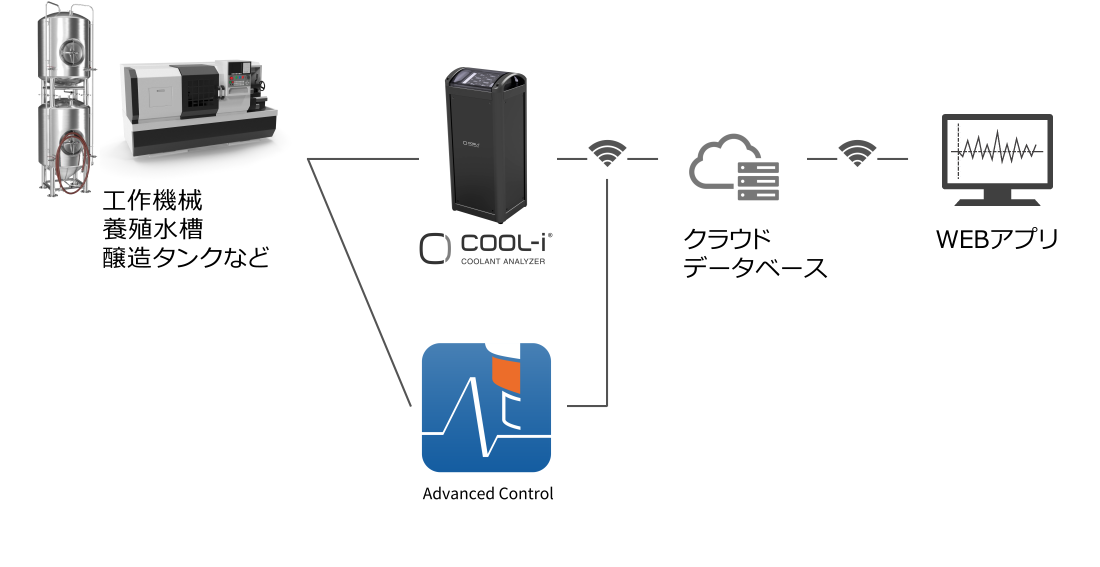

System Configuration DiagramSystem Configuration

Achieve appropriate coolant management

by maximizing the effect of cutting oil and suppressing processing quality issues.

As a result, it becomes possible to achieve appropriate coolant management, maximizing the effect of cutting oil and suppressing problems.

Case Studiescase

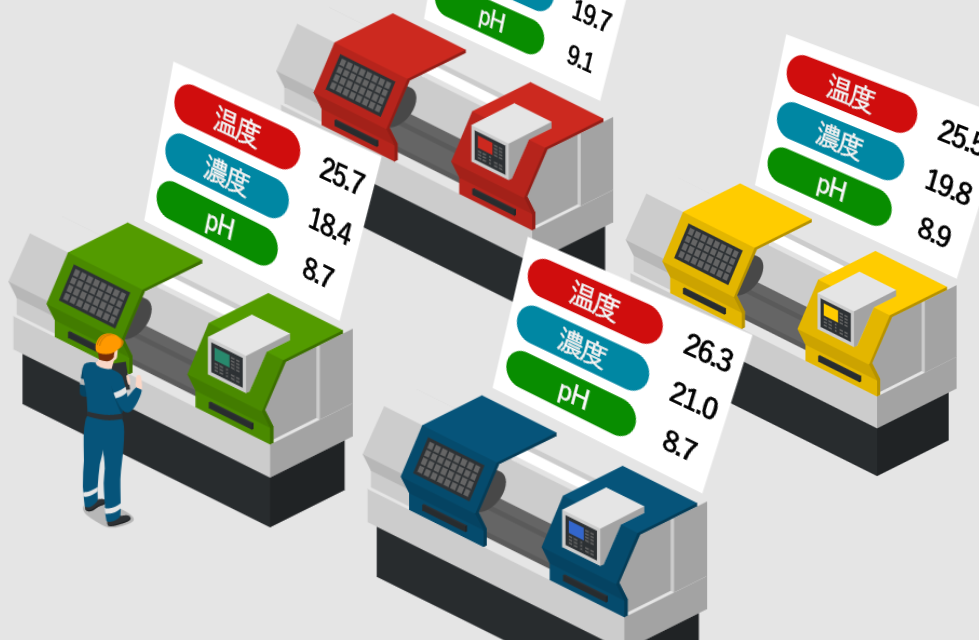

By introducing COOL-i, the hassle of daily coolant management has been eliminated.

At a certain factory, coolant checks were performed daily on 20 machine tools.

Coolant was sampled, checked with a device, and the record was written down on paper.

After introducing COOL-i, these routine tasks can now be checked and recorded on a PC or tablet without even going to the factory.

FAQFAQ

We have compiled frequently asked questions.

We welcome questions other than those listed below, so please feel free to contact us.

- What is COOL-i?

- It is a system that can monitor the temperature, concentration, pH, contamination level, ORP, etc., of water-soluble cutting oil 24 hours a day, 365 days a year.

- What can be determined by monitoring temperature?

- Careful temperature management is necessary for machining high-precision parts. The temperature of cutting oil changes due to variations in ambient temperature and heat generation from machining. The temperature of the cutting oil affects the temperature of the workpiece, which can influence dimensional variation. For machining that requires strict dimensional control, temperature management is also important. Monitoring temperature is crucial for guaranteeing stable quality and identifying the cause of defects. Furthermore, spoilage, one of the problems with cutting oil, has a strong relationship with bacterial growth and temperature.

- What can be determined by monitoring concentration?

- The performance of cutting oil changes depending on the concentration. If a certain concentration range is not maintained, the original performance will not be demonstrated, leading to various problems. Continuously recording the concentration makes it easy to determine if the concentration of the replenishment liquid and the frequency of replenishment are appropriate.

- What can be determined by monitoring pH?

- The pH of cutting fluid is generally adjusted to be alkaline, but the pH decreases when bacteria proliferate. Furthermore, a decrease in pH creates an environment where bacteria are more likely to proliferate, leading to a vicious cycle and spoilage.

Therefore, it is necessary to monitor the pH and manage it within a certain range.

- What happens if cutting oil concentration management is neglected?

- If the concentration is too low, it can lead to machining defects, spoilage, and rust on the product or machining equipment. If the concentration is too high, it can cause foaming and stickiness, worsening the working environment, and reducing cooling performance, leading to tool temperature rise.

For example, we respond to

requests like these.Request Order

- We want to solve machining defects and worsening working environments related to coolant.

- Coolant management is not being done adequately.

- We are unsure if the coolant’s effects are being fully demonstrated.

Flow until Order / RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate through meetings either by visiting or using a web conferencing system.

You will be asked to provide necessary information for installation.

It is also possible to observe what kind of test machine COOL-i is in advance.

- TOP

- Product Information

- COOL-i®

COOLANT ANALYZER