Four-Station Rotary Bending Fatigue Testing

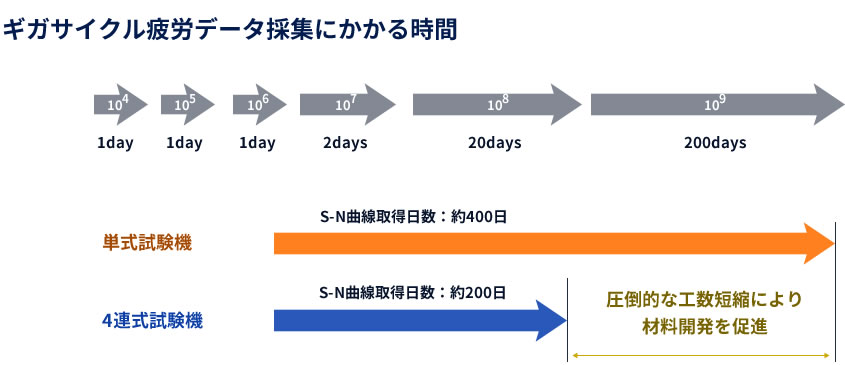

Accelerate material development

with overwhelmingly reduced man-hours

Optimal for testing costly

additive manufacturing materials

Significantly reduced test period

at about twice the normal speed

Testing under assumed environmental

conditions where metal is actually used is also possible

GIGAQUAD® is a testing machine that achieves efficient and very high reproducibility through the adoption of a four-station system.

Since four test pieces can be tested simultaneously, data acquisition is fast, and S-N curve creation can be performed efficiently.

We provide a consistent service from the production of test pieces for GIGAQUAD® to contract testing.

Flow of Rotary Bending Fatigue Contract Testing Service

Consultation on Test Piece Shape

We will consult on the outer diameter, total length, notch diameter, etc.

※Experience with small-diameter test pieces such as Φ5 is available

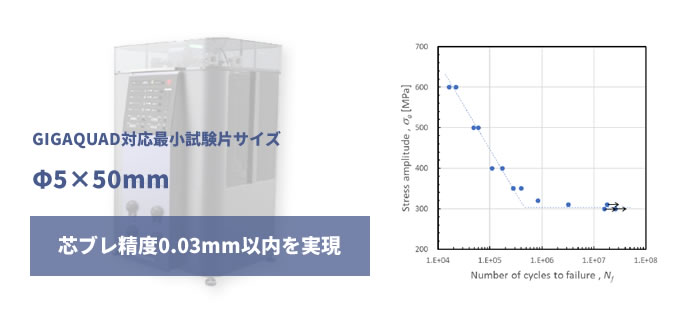

| Test Piece Shape Constraints | Significant reduction in material cost is possible Accelerates new material development. It is highly costly for most tests. GIGAQUAD® minimum compatible test piece size is φ5X50mm Optimal for testing especially costly **Additive Manufacturing** materials |

|---|---|

| Testing Accuracy | Runout accuracy of within 0.03mm is achieved ・Collet type is adopted for test piece clamping ・In-house manufactured high-precision spindle is adopted |

Benefits of using Yamamoto Kinzoku Seisakusho’s Material Testing Service and

Four-Station Rotary Bending Fatigue Testing

- Significant reduction in material cost is possible

- Optimal for testing especially costly additive manufacturing materials

- Highly reliable data acquisition is possible

Receipt of Test Piece Material

We can handle iron, stainless steel, aluminum, brass, Inconel, resin,

quenched steel, additive manufacturing materials, and various other materials. We also offer integrated support for surface treatments such as quenching,

plating, and anodizing.

Machining

We utilize the metal machining expertise cultivated since our founding to finish the test pieces with high precision.

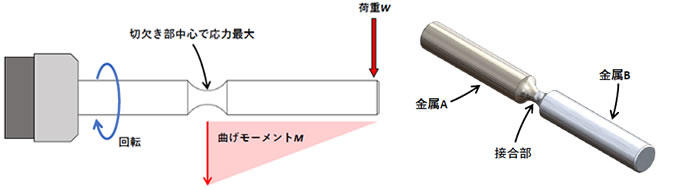

In rotary bending fatigue testing, it is possible to control the location of fatigue strength measurement.

Therefore, highly flexible fatigue design becomes possible.

For example, the **welding of dissimilar metals or additive manufacturing**, and furthermore, the **joint of friction stir welding** can be evaluated. This is a **unique advantage of the cantilever test piece with a notch section**.

Execution of Rotary Bending Fatigue Test

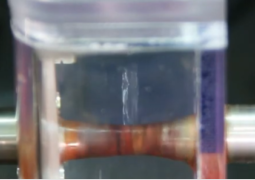

We perform rotary bending fatigue tests using test pieces manufactured with our GIGAQUAD®. Since we have corrosion environment units and high-temperature environment units, testing under assumed environmental conditions where metal is actually used is also possible.

Corrosion Environment Unit

Corrosion Environment Unit Concentrated Heating Unit

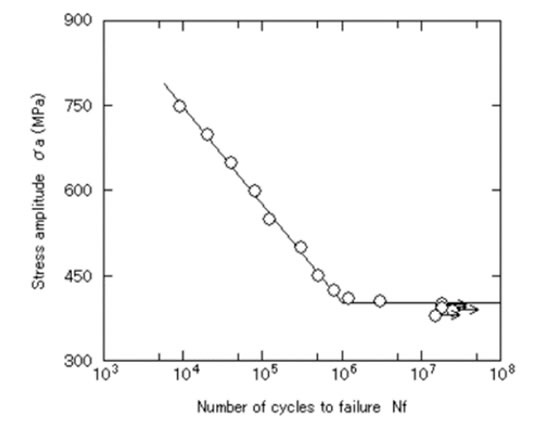

Concentrated Heating UnitDerivation of S-N Curve

Our GIGAQUAD® is a four-station system, allowing for highly efficient testing.

Please refer below for the JIS standard-defined high-speed loading rotary bending fatigue testing method for aluminum alloys and magnesium alloys.

JISZ3147:2017 High-speed loading rotary bending fatigue testing method for aluminum alloys and magnesium alloys (kikakurui.com)

For example, we respond to these requests.Request Order

- I want to perform a test, but the schedule for the testing machine I own is full

- I want you to handle everything from test piece production

- I want to perform rotary bending fatigue tests efficiently

- I want to perform fatigue tests assuming the actual environment

- Since the material is expensive, I want to conduct fatigue tests with small test pieces

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the test specifications through a visit or a web conferencing system meeting.

We will submit a quotation based on the test specifications.

It is also possible to visit and inspect what kind of testing machine GIGAQUAD® is.

- Witnessing the test is possible

- If you actually place an order, witnessing the test is possible.

Please feel free to contact us.

- TOP

- Business Introduction

- Material Testing Service