Machinability Evaluation Testing that “Visualizes”

Machining Phenomena

The advanced technology that supports our rich lives is constantly evolving.

Furthermore, in order to survive in an ever-expanding global competition, research and development with an eye to the future is extremely important.

Yamamoto Kinzoku uses its unique measurement and evaluation technology through machinability evaluation testing to deepen technology and build efficient processes,

thereby realizing the “visualization” of machining phenomena and working as a joint research partner to solve your company’s challenges.

I want to know better conditions than the current machining conditions

I want to know the machinability of new tools, new materials, and new cutting fluids

Shortage of staff, machinery, and time for evaluation testing

By conducting quantitative analysis instead of relying on the intuition of experienced personnel for comparison with conventional methods,

it can lead to reliable reduction in machining time, quality improvement, and research and development.

Testing is possible on both NC lathes and machining centers.

We have experience and achievements in testing difficult-to-machine materials (SUS440, SUS630, Ti-6Al-4V, Inconel, Hastelloy, Stellite, etc.).

The measurement and evaluation equipment and testing facilities that can be used can be confirmed here.

●Cutting Fluid Evaluation Test ●Turning Test for various stainless steels ●Boring Bar Machinability Evaluation

●MQL Drill Cutting Test ●Machining Simulation for newly developed steel ●Cutting Edge Temperature Measurement Test

●End Mill Cutting Resistance Evaluation Test ●Deep Hole Machining Test ●CFRP Machinability Evaluation, etc.

Evaluation Criteria for Machinability Evaluation Testing

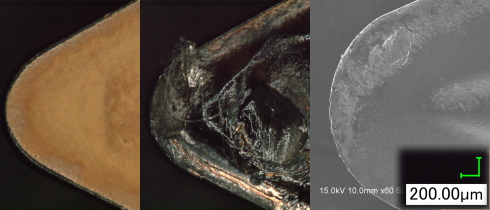

Tool Wear

The cutting edge of a tool is subjected to high temperature and high load during cutting, and it inevitably wears.

We conduct tests under various conditions and quantify the amount of tool wear.

In addition, component analysis of the worn part can be performed using an SEM (Scanning Electron Microscope).

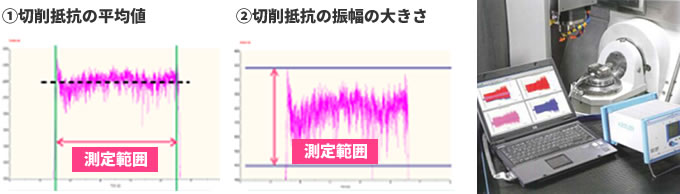

Cutting Resistance

Cutting resistance is the resistance (force) generated between the cutting tool and the workpiece during machining.

We use a cutting dynamometer manufactured by Kistler to quantify the resistance applied during cutting.

If the value of the cutting resistance is large, it can be judged that the cutting load is large and the sharpness is poor.

Also, if the amplitude of the cutting resistance is large, it indicates unstable cutting and a high risk of imminent tool damage.

Thus, by comparing the magnitude of cutting resistance and its amplitude, it is possible to predict the superiority or inferiority of tool life in a short period.

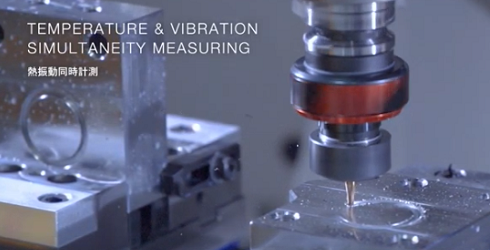

Temperature Measurement

The thermal energy generated during cutting is significantly related to tool life.

We measure the temperature of the tool and material during cutting using MULTI INTELLIGENCE®, thermography, and thermocouples to evaluate the temperature transition and distribution. MULTI INTELLIGENCE® is a monitoring device capable of real-time monitoring of the tool temperature during cutting. Temperature measurement while applying coolant is also possible (inner-through compatible). It is also possible to measure the temperature of the drill cutting edge, which could not be measured with infrared thermography. (#30, #40, #50 compatible. Custom products require consultation)

Monitoring using infrared thermography is also possible.

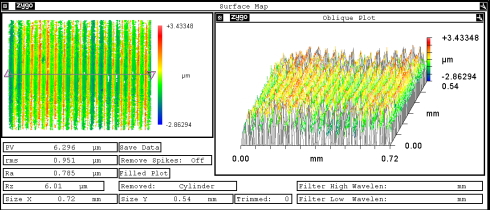

Surface Roughness

By using a non-contact surface roughness meter from Zygo, not only can the surface roughness be measured,

but the built-in interferometer also allows for 3D visualization of the surface.

Observation of the machined affected layer using a field-emission scanning electron microscope is also possible.

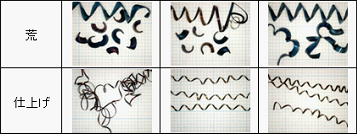

Chip Shape and Color

By visualizing the chip shape and separability, it is possible to grasp the risks associated with each condition.

It is also possible to check the chip discharge status using a high-speed camera.

Comparison of chip shapes by condition

Comparison of chip shapes by condition Observation of chip discharge status with a high-speed camera

Observation of chip discharge status with a high-speed cameraList of Measurement and Evaluation Equipment

| Manufacturer | Measurement and Evaluation Equipment Name |

|---|---|

| 日本キスラー㈱ (Kistler Japan Co., Ltd.) | Cutting Dynamometer 9255B |

| Cutting Dynamometer 9255C | |

| Cutting Dynamometer 9129AA for NC | |

| Cutting Dynamometer 9129AA for MC | |

| Rotary Cutting Dynamometer 9170A | |

| ㈱キーエンス (Keyence Co., Ltd.) | High-Speed Camera VW9000 |

| Microscope VW9000 | |

| 日本アビオニクス㈱ (Avio Co., Ltd.) | Infrared Thermography H2640 |

List of Testing Facilities

BT50 compatible

5-axis MC

BT40 compatible

Vertical MC

BT30 compatible

Vertical MC

| Manufacturer | Machine Name | Max Machining Diameter × Max Length | Standard / Specification | Spindle Speed | Spindle Inch (size) | Through-Spindle Coolant | Coolant Pressure |

|---|---|---|---|---|---|---|---|

| DMG森精機㈱ (DMG Mori Seiki Co., Ltd.) | NT4250 DCG/1000SZ |

φ660×1027 | 5-axis Multi-Tasking Machine | 4000 | 10 | 〇 | Manufacturer Standard |

| NL3000Y/1250 | φ420×1260 | Chucker with Y-axis | 4000 | 12 | × | Manufacturer Standard | |

| NL2500Y/700 | φ366×705 | Chucker with Y-axis | 3000 | 10 | × | Manufacturer Standard | |

| シチズンマシナリーミヤノ㈱ (Citizen Machinery Miyano Co., Ltd.) | BNC34C | φ34×150 | Bar Stock Processing Machine | 4000 | × | Manufacturer Standard |

| Manufacturer | Machine Name | Table Work Surface Size | Standard / Specification | Spindle Speed | Spindle Standard | Through-Spindle Coolant | Coolant Pressure |

|---|---|---|---|---|---|---|---|

| DMG森精機㈱ (DMG Mori Seiki Co., Ltd.) | DMU 80 FD duoBLOCK | Ø 800 | 5-axis Multi-Tasking Machine | 12000 | HSK100A | 〇 | 6.8Mpa |

| NMV5000 DCG | φ500 | 5-axis Multi-Tasking Machine | 20000 | BT40 | 〇 | Manufacturer Standard | |

| NMV8000 | φ800 | 5-axis Multi-Tasking Machine | 15000 | BT50 | 〇 | 7Mpa | |

| NV5000α1B/40 | 1,320×600 | Vertical MC | 14000 | BT40 | 〇 | 7Mpa | |

| NVX5100Ⅱ/50 | 1,350×600 | Vertical MC | 8000 | BT50 | 〇 | 7Mpa | |

| MV-55/50 | 1400×550 | Vertical MC | 6000 | BT50 | × | Manufacturer Standard | |

| NHX5500 | 500×500 | Horizontal MC | 8000 | BT50 | 〇 | Manufacturer Standard | |

| ファナック㈱ (FANUC Co., Ltd.) | α-D21LiB BBT30 | 850×410 | Vertical MC | 10000 | BT30 | 〇 | Manufacturer Standard |

| ㈱牧野フライス製作所 (Makino Milling Machine Co., Ltd.) | V56i | 1050×550 | Vertical MC | 20000 | HSK-A63 | 〇 | 7Mpa |

| 安田工業㈱ (Yasuda Kogyo Co., Ltd.) | YBM Vi40 | φ400 | 5-axis Multi-Tasking Machine | 24000 | BBT40 | 〇 | 6.9Mpa |

For example, we respond to these requests.Request Order

- I want to test the performance of new materials and new products

- I want to know the optimal machining conditions for machined parts

- I want to reduce tool costs

- I want to reduce machining time compared to now

- I want to convert technology that relies on human intuition into data

- I want to conduct experiments but lack equipment and time

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the test specifications through a visit or a web conferencing system meeting.

We will submit a quotation based on the test specifications.

- Witnessing the test is possible

- If you actually place an order for the Machinability Evaluation Test Service, witnessing the test is possible at the Okayama Research and Development Center.

Please feel free to contact us.

- TOP

- Business Introduction

- Machinability Evaluation Test Service