Patented Patent No. 7068567

Providing Residual Stress Measurement

Solutions

Applicable to Thick Plates

Measurement possible even for test pieces with a thickness of 100mm or more

(Measurement possible from a depth of 1mm)

Accuracy of Measurement Position Determination

Position determination is performed by machine control, allowing control with an accuracy of ±1μm

Compatibility with Complex Shapes and Various Material Types

Small shape constraints,

measurement possible even for complex shapes

Steel, non-ferrous metals, resins, special materials

and various other material types are supported

Suppression of Machining Volume

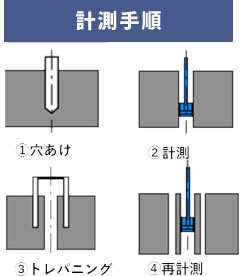

Measurement possible only by drilling + trepanning at the measurement position

Since the machining volume is suppressed,

short delivery times and reduced measurement costs are realized

Stress remains in materials due to processing such as casting, forging, welding, grinding, shot peening, and heat treatment.

Residual stress can cause stress corrosion cracking, fatigue cracks, and brittle fracture in structures.

Therefore, appropriate structural design, metal processing, new material development, and construction management based on the understanding of residual stress are indispensable for ensuring the reliability of structures and various processed parts.

Yamamoto Kinzoku utilizes the technology we have cultivated in cutting, drilling, and polishing metals, and

our expertise in measuring and evaluating materials, to provide various residual stress measurement services.

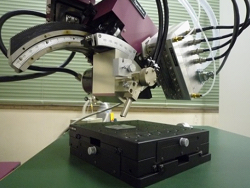

The MIRS® method is a high-precision internal residual stress measurement method using the deep hole drilling technique, leveraging our accumulated machining technology.

All processes are carried out in Japan, allowing us to respond with shorter delivery times and perform measurement and evaluation.

![]()

What is the MIRS® Method?

The High-Precision Internal Residual Stress Measurement Method (Deep Hole Drilling Method) is an improvement of the deep hole drilling method developed in the UK,

jointly conducted by Yamamoto Kinzoku Seisakusho, Osaka University, Kobelco Welding Techno Co., Ltd., and Okayama Prefectural Industrial Promotion Foundation.

This measurement is a residual stress measurement method capable of measuring inside thick plates.

This method can be applied to measure residual stress inside thick plates of 100mm or more. It is applicable from a plate thickness of 4mm. It has also been proven for thin plates and steel pipes.

*Measurable plate thickness: 4mm to 200mm *Measurable weight: up to 10t

●Understanding the internal residual stress distribution of various steel, thick aluminum plates, and forged materials

●Understanding the internal residual stress distribution in brake discs

●Residual stress measurement of automobile axles

●Residual stress measurement of additive manufactured materials and laser beam shaped materials

●Actual value measurement of internal residual stress distribution in resin materials (epoxy resin, PP, etc.)

●Residual stress measurement of resin molded products under injection molding conditions

●Confirmation of peening effect

●Validation of FEM analysis results

●Validation of welding simulation validity

●Confirmation of crack propagation behavior, etc.

●Residual stress measurement of 0~1mm on the front and back surface using a touch probe

Measurement results have also been achieved for resin materials (epoxy resin, PP, etc.) and CFRP.

Measurement examples for various materials: Iron (SS400, etc.), Stainless steel (SUS304, etc.), Aluminum (A5052, etc.), Resin (polyamide resin, etc.), Inconel, Titanium

About MIRS® Method Measurement

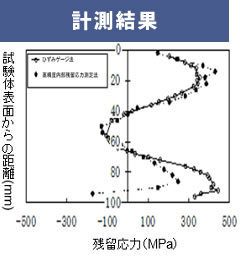

Comparison with Strain Gauge Cutting Method

| Strain Gauge Cutting Method | Internal Residual Stress Measurement MIRS® Method | |

|---|---|---|

| Material | Steel, non-ferrous metals, resin | Steel, non-ferrous metals, resin |

| Measurement Depth | Measurement depth 2 to 100mm or more (However, limited to simple shapes) |

0 to 100mm or more (Complex shapes possible) |

| Measurement Pitch | 2mm to | 0.2mm to |

| Measurement Position Error | Attachment position ±0.5mm Gauge inclination approx. ±1° |

Approx. ±1μm |

| Machining Volume | Requires cutting until it becomes a block of approx. 1.5mm machining volume | Drilling + trepanning at the measurement position ⇒ Ultimate minimization of destruction volume |

| Required Days | 4 to 8 weeks (Depending on the number of measurement pitches) |

Approx. 2 weeks |

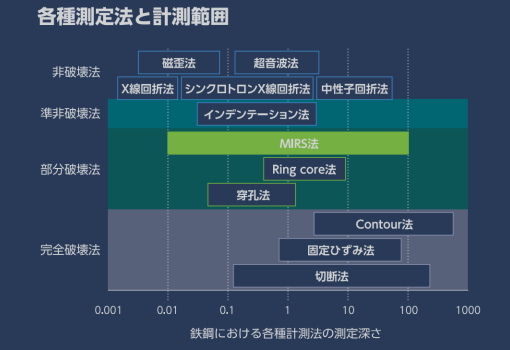

Measurement Depth in Various Measurement Methods

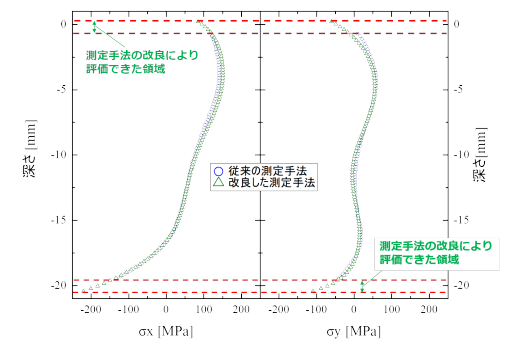

By improving the evaluation method, residual stress of 0 to 1mm on the front and back surface can be evaluated using the MIRS® method.

Please utilize it for evaluating small, thin-walled products and materials.

Strain Gauge Method

This is a method of measuring the released stress by affixing a strain gauge to the area of the inspection object where residual stress or strain is to be measured, considering the measurement direction, and cutting around the strain gauge.

It is suitable for macroscopic stress measurement acting on the entire area where the strain gauge is attached.

Application example: Confirmation of residual stress inside plate thickness

X-ray Diffraction Method

When stress is applied to a material, the distance between the aligned atoms (lattice spacing) also expands and contracts.

The X-ray diffraction method measures the change in lattice spacing using X-rays.

The stress measurement depth is in the range of several μm from the surface and is suitable for microscopic stress measurement acting on a minute area.

Application example: Confirmation of shot peening effect

What is Residual Stress?

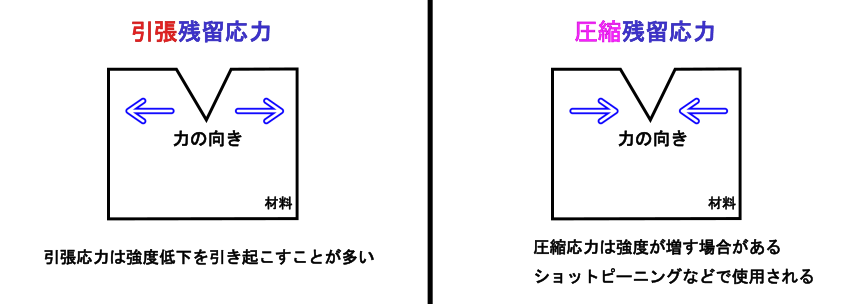

Even when no external force is acting on a material or structure, there may be stress statically balanced internally,

and such internal stress is called residual stress.

Stress has a direction. The stress generated when an object is pulled and attempts to stretch due to an external force is called tensile stress,

and conversely, the stress generated when an object is attempted to be compressed by an external force is called compressive stress. Tensile stress often reduces the strength of an object,

while compressive stress often increases the strength of an object.

There is also a treatment method called shot peening that improves strength by utilizing the characteristics of compressive stress.

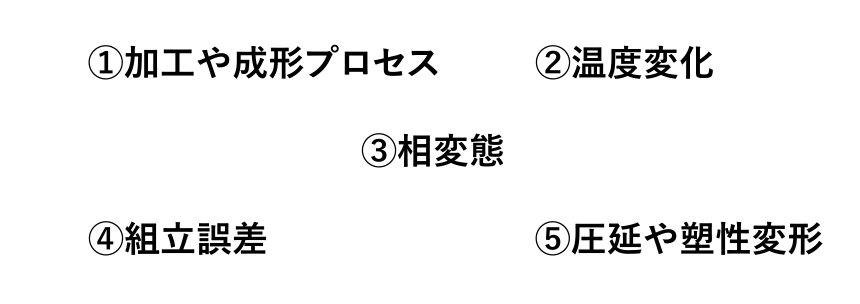

Causes of Residual Stress Generation

1: Machining and Forming Processes

Residual stress is generated when a material is subjected to excessive localized force during machining processes such as welding, forging, casting, bending, and drawing.

Especially in cold working, large residual stress is likely to occur inside the material after processing.

2: Temperature Changes

Residual stress is generated when the partial expansion and contraction within the material are not uniform due to a temperature gradient caused by rapid cooling or heating.

For example, internal stress may occur due to the rapid cooling of the surface and the temperature difference with the interior during quenching.

3: Phase Transformation

Phase transformation within the material (e.g., martensitic transformation during steel quenching) causes volume change, which can result in residual stress remaining internally.

4: Assembly Errors

When parts are assembled, if there are dimensional errors or misalignment of assembly conditions, non-uniform forces act between the parts, causing residual stress.

5: Rolling and Plastic Deformation

When a material undergoes rolling or plastic deformation, strain occurs inside the material, and stress remains without being removed.

In any case, residual stress is closely related to machining accuracy, so it must be properly addressed during processing.

Yamamoto Kinzoku offers the MIRS® method for measuring and analyzing such residual stress.

If you want to know more about residual stress, please go to the Residual Stress Story page here.

Frequently Asked Questions

We have compiled frequently asked questions about the residual stress measurement solution service from everyone.

We also welcome questions other than those listed below, so please feel free to contact us.

- Is the MIRS® method non-destructive or destructive?

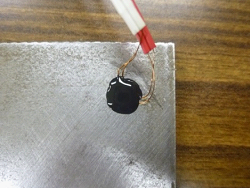

- Since drilling + trepanning is performed at the measurement position, the volume of destruction is minimized, but

it is not a non-destructive method. Its position is that of a partially destructive method.

- What is the hole diameter measured by the MIRS® method?

- It is φ2.5 or φ6.

- What are the measurable material shapes with the MIRS® method?

- It applies to workpieces of φ25 or more or □25 or more that can be placed on a 6m x 3m table.

- What materials are compatible with the MIRS® method?

- Metals or resins are compatible.

- What is the flow of contract testing for the MIRS® method?

- ①Place an order

②Send the test specimen to our Okayama R&D Center

③Measurement

④Return the data and test specimen

That’s all.

- Is there a way to remove residual stress?

- For metal products, there is a heat treatment called annealing, which removes internal strain.

For resin products (plastics), there are methods of applying heat such as annealing or after-baking.

For details, please refer to the Keyence website.

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the test specifications through a visit or a web conferencing system meeting.

We will submit a quotation based on the test specifications.

- Witnessing the test is possible

- If you actually place an order for the residual stress measurement solution service, it is possible to witness the test at the Okayama R&D Center.

Please feel free to contact us.

- TOP

- Business Introduction

- Residual Stress Measurement Solution Service