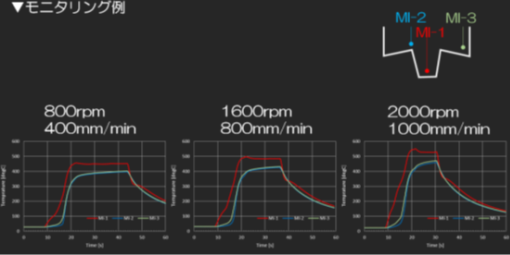

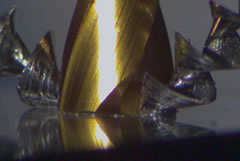

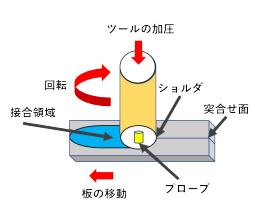

先端に突起のある円筒状の工具(ツール)を回転させながら強い力で押し付けることで突起部を接合させる部材(母材)の接合部に貫入させ、これによって摩擦熱を発生させて母材を軟化させるとともに、工具の回転力によって接合部周辺を塑性流動させて練り混ぜることで複数の部材を一体化させる接合法です。

英語ではFSW(Friction Stir Welding)と呼ばれ、直訳した摩擦攪拌溶接という用語が利用される場合もあります。

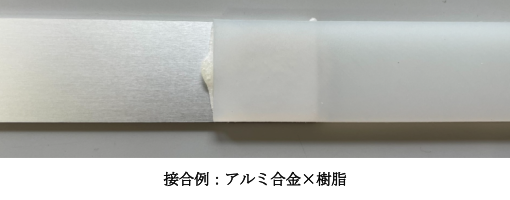

長所としては、接合部の熱影響を抑制できる、シールドガスが不要、騒音や粉塵の発生を低減できる、

という事が挙げられます。

ツール

FSW(摩擦攪拌接合)模式図