Q&A

About GIGA QUAD®

What is the superiority of the rotating bending machine comparing with the ultrasonic machine?

These 3points are fundamental advantages of the rotating bending machine.

- Heat generation of the specimen takes place in the case of ultrasonic tests.

- When we use the ultrasonic fatigue instrument, the shape of a specimen is restricted depending on the resonance conditions. But, we can perform fatigue tests for various shapes of specimens, if we use the rotating bending fatigue testing machine here explained.

- S-N characteristics depend on the loading frequency.

This fact is repeatedly confirmed by many researchers all over the world.

Thus, it is very difficult to obtain the real S-N property at usual frequency(50Hz/60Hz) by using the ultrasonic fatigue testing machine.

What is the difference between both-handed type and one-handed type?

When both-handed type is used, the loading type becomes “uniform bending”, while when one-handed type is used, the loading type is cantilever bending.

In the case of cantilever bending, the bending stress increases depending on distance from the loading point.

So hourglass type of specimens is accepted to keep the fracture at the critical portion.

Based on such a situation, the effective volume of the specimen in the cantilever bending is a little smaller than that in the uniform bending.

Thus, fatigue strength in the cantilever bending would be a little higher than that in the uniform bending.

But, the difference is usually very small within a few percents.

That is the reason why many users have already used one-handed type.

We have already performed fatigue test by axial loading. But furthermore, do we have to performed fatigue test by rotating bending.

The loading types between axial loading and rotating bending are different.

In the case of axial loading is uniform on the critical section.

While in the case of rotating bending is graduated, that is ,the loading on the surface is maximum, but the loading of the center is zero.

Therefore, especially effect of surface treatment on the fatigue strength makes quite different between them.

Thus, both types of fatigue tests are important to make sure the fatigue property.

This is our fundamental standpoint to develop the rotating bending testing machine.

What is the maximum value of stress based on the test?

The most difficult subject was the development of high performance spindle having a small eccentricity.

If the eccentricity becomes large, problems of vibration and noise take place in the fatigue tests, and some extent of error is included in the applied stress.

Actually, the reason why we can keep such a small eccentricity is to use a collet chuck and a collet nut.

But there is another main reason. That is the precision of shape and dimensions of the spindle and every component around the spindle.

How can we produce those precise parts?

And how can we assemble these parts?

This is the most important and difficult subject to develop the high performance machine.

What is the maximum value of stress based on the test?

With standard specimen:

For YRB200 type: 1,363MPa

For YRB300L type: 2,540MPa

What are the maximum and minimum load values?

For YRB200 type: The maximum load is 20kg; the minimum load is 0.49kg. Without any weights, the load is 0.47kg already due to the weight of adaptor, spring, rod, saucer and nut. For YRB300L type: The maximum load is up to 85kg; the minimum load is 5.21kg.

What is the possible size of the collet chuck?

The possible outside diameter of specimen is φ5 ~φ13 for YRB200; φ5 ~φ20 for YRB300L.

However, fatigue testing result will be affectted by many factors such as dimension effect and stress concentration, so we highly recommend the specimen of our own shape and dimensions. Besides, the dimensions of collet and adaptor are determined, so in case of changing the outside diameter of specimen, further discussion is required to prepare another suitable collet and adaptor.

What is the required run-out tolerance of the specimen?

According to JIS Z 2274, the proposed run-out tolerance of specimen is less than ±25μm. Practically, we did conduct experiments on specimens of the two run-out tolerance: over ±60μm and under ±20μm. The result was as follows: the specimen which had run-out tolerance of over ±60μm had the fatigue limit lower by 20% compared to the other cases.

What is the difference between GIGA QUAD and Ono type-uniform rotating bending fatigue testing machine?

GIGA QUAD is cantilever type machine which can be used to test 4 specimens simultaneously, whereas the Ono is uniform type (both sides of the specimen are held during the test), which can test only one specimen at a time.

GIGA QUAD® Line up

It is possible to transfer the data to a PC via the in-house-developed wireless-measurement system which includes measuring instrument and transmitter built inside the tool holder.

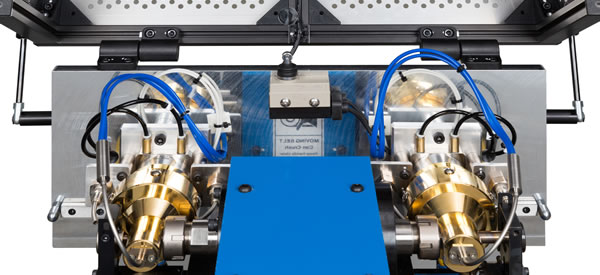

Dual-spindle rotating bending fatigue testing machine for low load type

YRB200

YRB200 was to be produced at high levels with high precision, high efficiency and less space.

It is suitable for the testing of giga-cycle fatigue characteristics which are supposed to take long time. It also has a variety of functions.

Dual-spindle rotating bending fatigue testing machine for high load type

YRB300L

YRB300L is a higher weight model adapted for metal fatigue strength characteristics reserch with high intensity and with heat treatment.

It is designed with safety for higher weight.

Corrosion environmental testing unit

for GIGA QUAD®

Corrosion environmental testing unit YRB200-010

YRB200-010 can easily make corrosive environment and adapt to the test following actual environment. It is possible to perform rotating bending fatigue test under the corrosive environment.

The perfect antiscattering design of corrosive solution is being applied for a patent.

High temperature environmental testing unit (Halogen Lamp) for GIGA QUAD®

High temperature environmental testing unit(Halogen Lamp)

It is necessary to clarify the reliability property of structural materials at high environmental temperature.A spot light-condensed heating method is adopted in the developed high temperature unit. The light emitted from the halogen lamp is reflected and condensed to the small spot in the center of specimen.