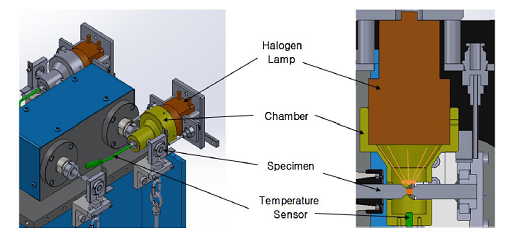

High temperature environmental testing unit

(Halogen Lamp)

In the applications of metallic materials to power and energy plants, the key components always work in a high temperature. For example, in the design of gas turbines, it is important to increase gas temperatures in order to attain a high thermal efficiency.

For jet engines, an increased temperature realize higher loads, higher speed and a greater output range. In the case of power generating gas turbines, the increase of temperature leads to lower fuel consumption, pollution and cost.

Thus, it is necessary to clarify the reliability property of structural materials at high environmental temperature.

The unit is expected to contribute to clarify the fatigue property and fracture mechanism at high environmental temperature.

A spot light-condensed heating method is adopted in the developed high temperature unit. The light emitted from the halogen lamp is reflected and condensed to the small spot in the center of specimen. The center of the specimen can be heated rapidly to the temperature of 600 deg.C.

A temperature sensor is used to measure the temperature inside the chamber. And the temperature inside the chamber is controlled to keep a given value set by the temperature control panel, through adjusting the input voltage of the lamp automatically. A water cooling system is used to protect lamp power components from over-heating. An air cooling system is used to cool the bearing of the adapter in the end of the specimen.

Specification

- Testing Temperature: Fe 100~600 deg.C、Al 100~250 deg.C

- Temperature Control: PID / Power Control

- Input ±5 deg.C

- Temperature Measurement: 1 deg.C(resolution)

- Size of Control Panel: W500*D500*H1400mm

- Specimen: YRB200- Φ10 (Standard)

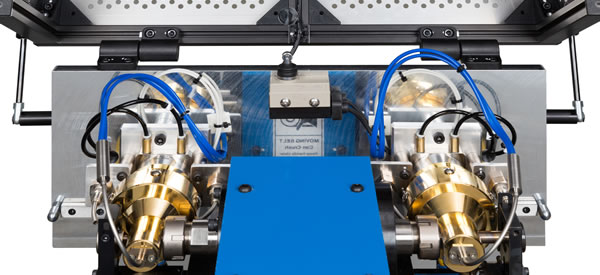

- Number of Chambers: 2 (Separate control)

※ Product specifications and appearance may be changed for the improvement. We appriciate your understanding.

GIGA QUAD® Line up

It is possible to transfer the data to a PC via the in-house-developed wireless-measurement system which includes measuring instrument and transmitter built inside the tool holder.

Dual-spindle rotating bending fatigue testing machine for low load type

YRB200

YRB200 was to be produced at high levels with high precision, high efficiency and less space.

It is suitable for the testing of giga-cycle fatigue characteristics which are supposed to take long time. It also has a variety of functions.

Dual-spindle rotating bending fatigue testing machine for high load type

YRB300L

YRB300L is a higher weight model adapted for metal fatigue strength characteristics reserch with high intensity and with heat treatment.

It is designed with safety for higher weight.

Corrosion environmental testing unit

for GIGA QUAD®

Corrosion environmental testing unit YRB200-010

YRB200-010 can easily make corrosive environment and adapt to the test following actual environment. It is possible to perform rotating bending fatigue test under the corrosive environment.

The perfect antiscattering design of corrosive solution is being applied for a patent.

High temperature environmental testing unit (Halogen Lamp) for GIGA QUAD®

High temperature environmental testing unit(Halogen Lamp)

It is necessary to clarify the reliability property of structural materials at high environmental temperature.A spot light-condensed heating method is adopted in the developed high temperature unit. The light emitted from the halogen lamp is reflected and condensed to the small spot in the center of specimen.