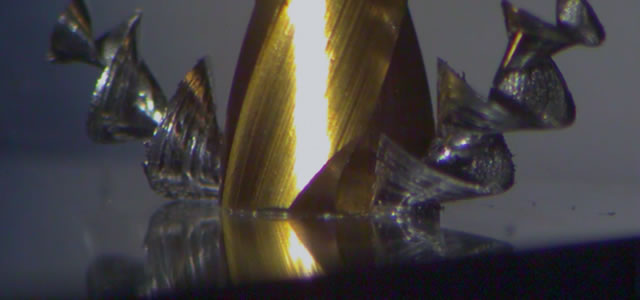

Precision Machining Machining Measurement & Evaluation Robot System Integration

We visualize the expertise cultivated over many years of experience through numerical values and

propose new manufacturing that merges digital technology and people.

Yamamoto Kinzoku Seisakusho, specialists in precision cutting and precision measurement & evaluation,

will inherit the technology that leads to a prosperous future and support global manufacturing.

Creating Innovation

in Machining

We provide optimal solutions to customers through the provision of precision machined parts, measurement and evaluation equipment, and various evaluation test services, based on the keywords of “materials, machining technology, and design capabilities.”

Furthermore, by applying and advancing the precision machining and measurement evaluation technologies cultivated so far,

we are promoting the Learning Factory concept with the “Machining Optimization Support Service.”

In the “Robot SI Business,” we are engaged in research and development of automation systems that are effective when introduced into high-mix low-volume production lines, mainly for small and medium-sized enterprises.

Machining Optimization Support Service

Developing services that promote the Learning Factory concept for all factories.

Proposing services tailored to customer challenges through “Expertise x Data x AI.”

Robot SI Business

Conducting research and development efforts to introduce robot systems compatible with high-mix low-volume production,

primarily for small and medium-sized enterprises.

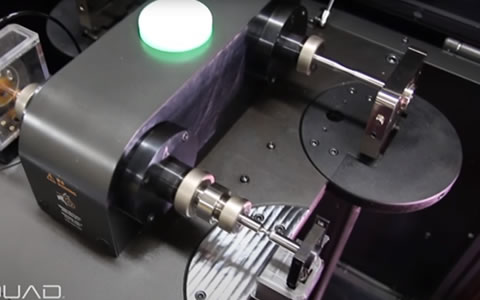

FSW Optimal Production Solution Service

It’s difficult to start testing FSW (Friction Stir Welding) because there is no in-house adoption record or precedent.

There are few opportunities to learn the FSW joining theory with practical training.

Yamamoto Kinzoku Seisakusho provides solutions for such problems.

Products

Solution for Industry

Yamamoto Kinzoku Seisakusho is compatible with all industries,

and we respond with industry top-level accuracy and speed tailored to customer needs, with a deep understanding of the unique prototypes and part characteristics of each industry.

Hydraulic Equipment Parts

- Cylinder blocks

- Pistons

- Crankshafts

- Valve plates

- Housings, etc.

- Mass production machining of various core parts

Energy and Infrastructure Fields

- Impellers for power generation equipment, pumps, and compressors

- Brake discs

- Guide vanes

- Nozzles

- Blades, etc.

Medical Field

- Biomaterial parts (stainless steel, titanium, etc.)

- Medical testing machine parts (for blood, urine, clinical use, etc.)

- Various precision micro-machining

Machine Tool Parts

- Flanges

- Pistons

- Sleeves

- Guides

- Housings, etc.

Fluid Equipment Parts

- Nipples

- Sockets

- Couplers

- Counter plates

- Actuator caps, etc.

- Various mass production support

Measurement and Evaluation Field

- Machinability evaluation and residual stress measurement of difficult-to-cut materials

(Inconel, CFRP, Ceramics, etc.) - Internal residual stress measurement of resin materials

- Cutting performance verification with cutting fluids

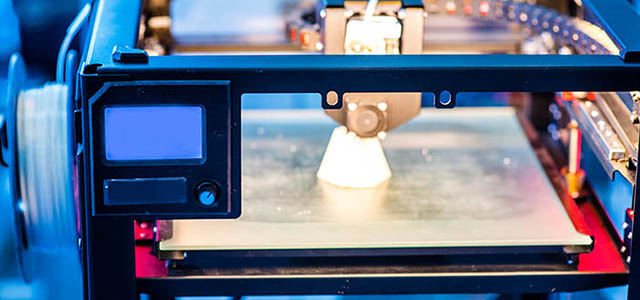

- Fatigue strength evaluation of additive manufacturing materials

- Validation of Friction Stir Welding (FSW), etc.

- Various education support services

Hydraulic Equipment Parts

- Cylinder blocks

- Pistons

- Crankshafts

- Valve plates

- Housings, etc.

- Mass production machining of various core parts

Energy and Infrastructure Fields

- Impellers for power generation equipment, pumps, and compressors

- Brake discs

- Guide vanes

- Nozzles

- Blades, etc.

Medical Field

- Biomaterial parts (stainless steel, titanium, etc.)

- Medical testing machine parts (for blood, urine, clinical use, etc.)

- Various precision micro-machining

Machine Tool Parts

- Flanges

- Pistons

- Sleeves

- Guides

- Housings, etc.

Fluid Equipment Parts

- Nipples

- Sockets

- Couplers

- Counter plates

- Actuator caps, etc.

- Various mass production support

Measurement and Evaluation Field

- Machinability evaluation and residual stress measurement of difficult-to-cut materials

(Inconel, CFRP, Ceramics, etc.) - Internal residual stress measurement of resin materials

- Cutting performance verification with cutting fluids

- Fatigue strength evaluation of additive manufacturing materials

- Validation of Friction Stir Welding (FSW), etc.