Utilization of 3D Printers

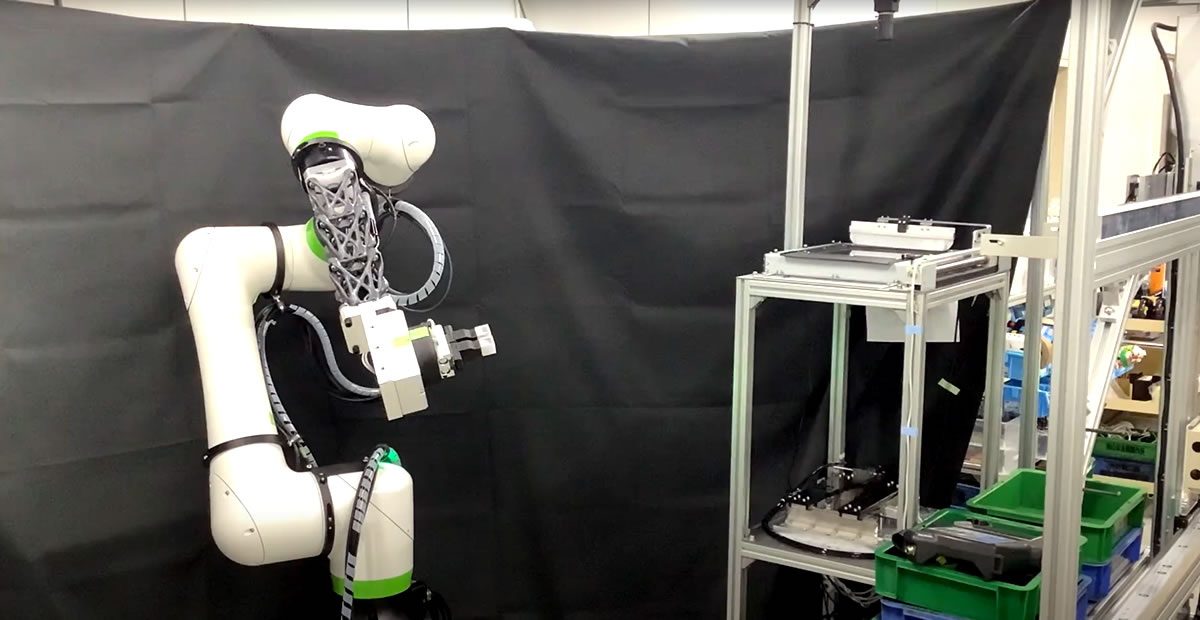

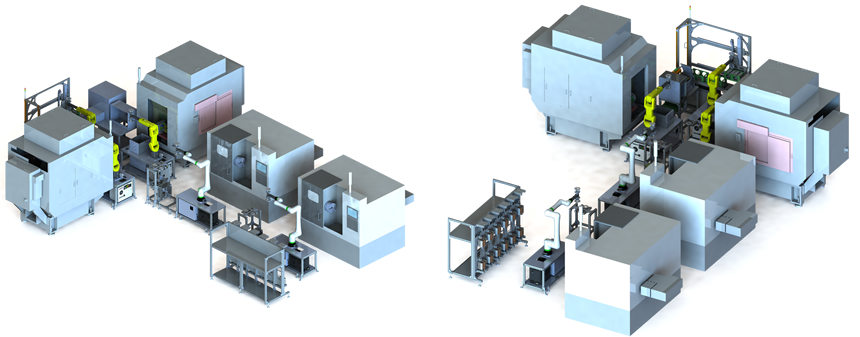

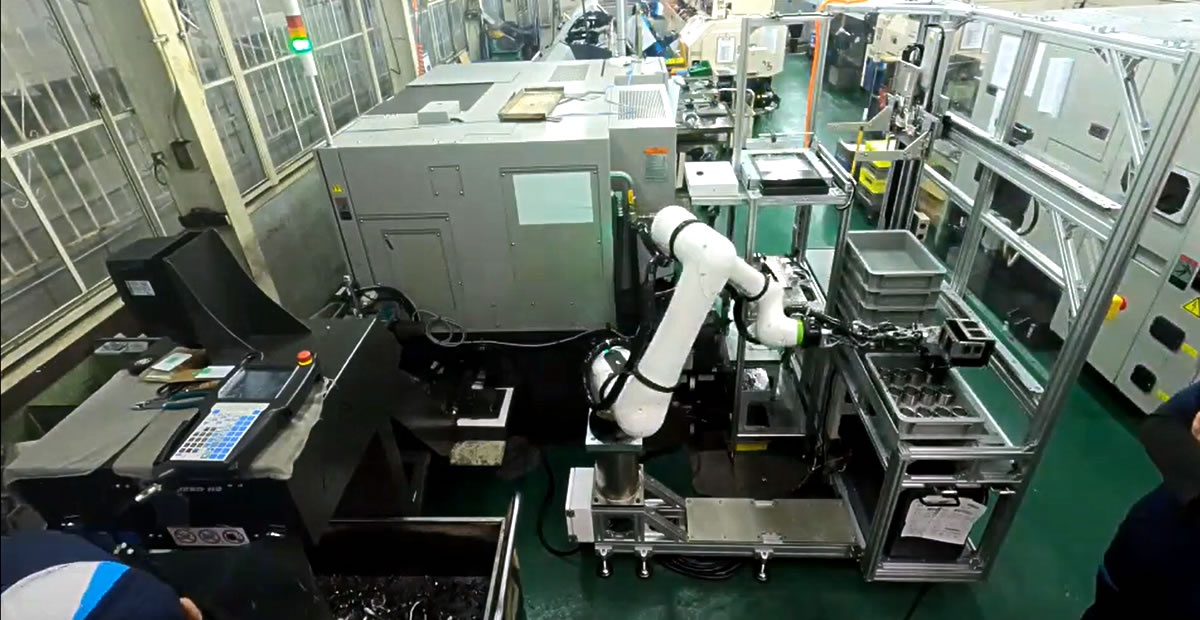

As an initiative unique to Yamamoto Kinzoku, we are engaged in production activities that integrate 3D printers, robotics,

and machining.

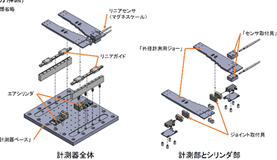

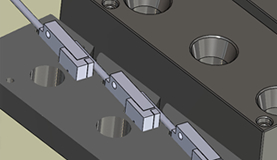

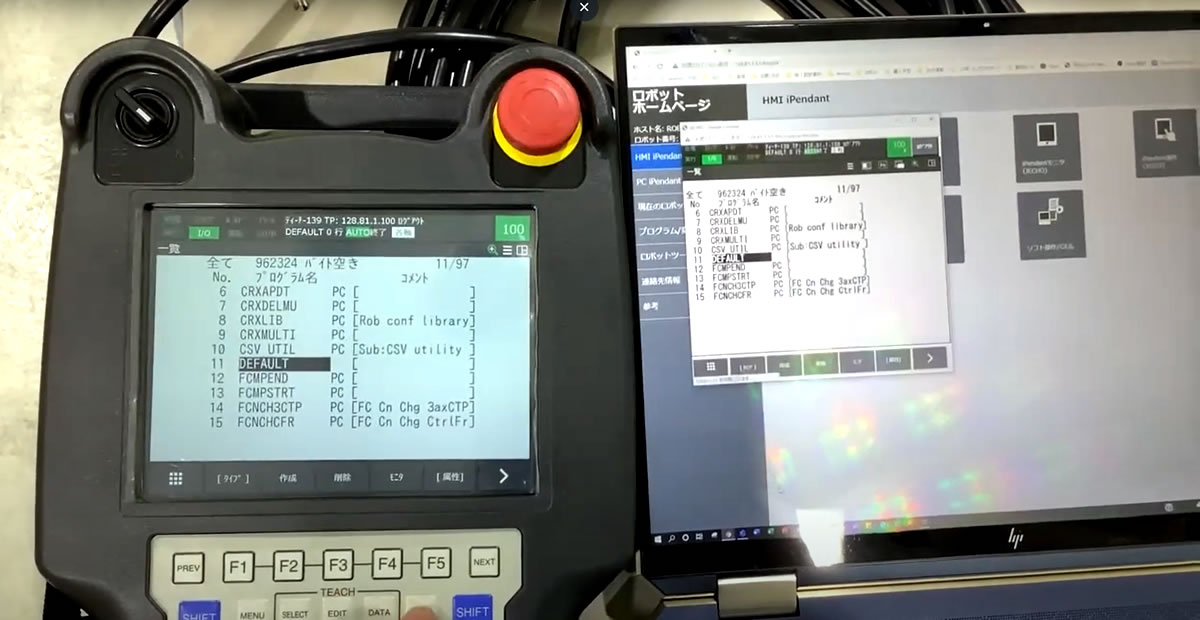

We perform dedicated design of jigs and support parts with a 3D printer and create robot arms with built-in sensors, hands, and measures against dents.

We add high value by incorporating Yamamoto Kinzoku’s core technologies such as precision machining technology, and data collection and utilization such as sensing.

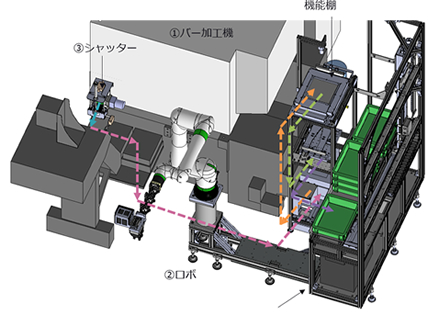

Example of Initiative

Creation of Robot Arm

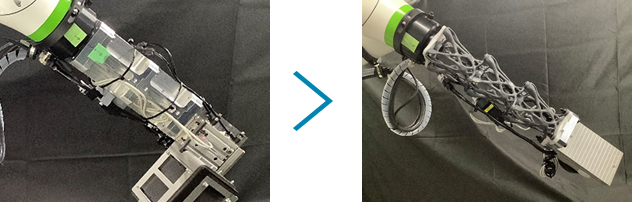

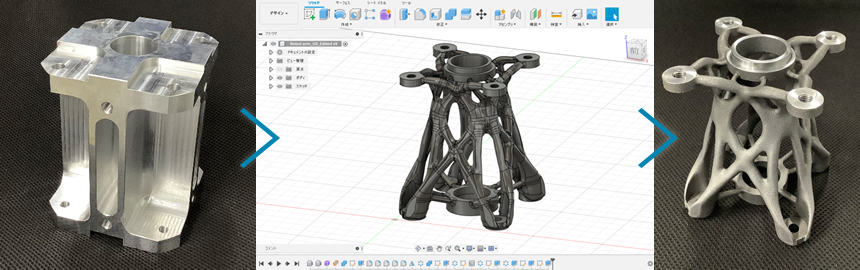

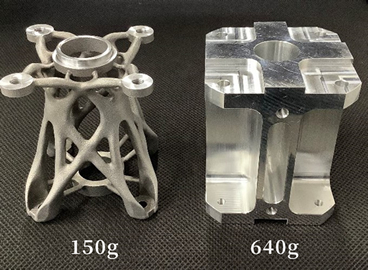

Conventionally, arm blocks were made by cutting, but we pursued cost reduction for workpiece stable operation, improved safety through weight reduction, and machining arrangement/inventory management, and attempted to mold arm blocks using a 3D printer.

We set parameters such as function, space conditions, materials, and manufacturing method using Generative Design, found the optimal shape, and performed modeling with a 3D printer.

※What is Generative Design… A type of design review process that sets parameters such as function, spatial information, materials, and manufacturing method, finds possible solutions, and generates them.

Features of Yamamoto Kinzoku Robot Hand

● Weight reduction and improved design of conventional parts using Generative Design

● Acceleration of the process from design to product completion

● Robot size reduction and total system cost reduction through weight reduction

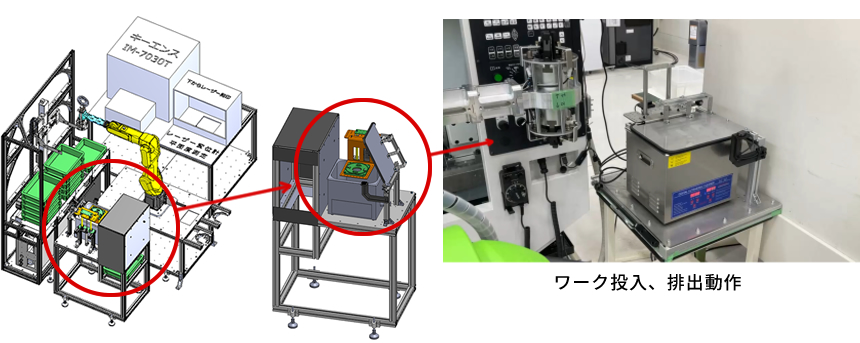

The state of the workpiece can be recognized by a 3D-printed jig with embedded sensors.

Weight reduction was also achieved by embedding the sensor inside.