Company A: Responsible for “Production Technology”

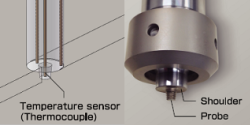

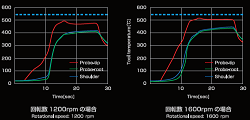

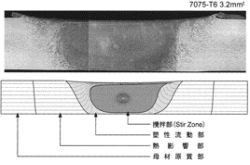

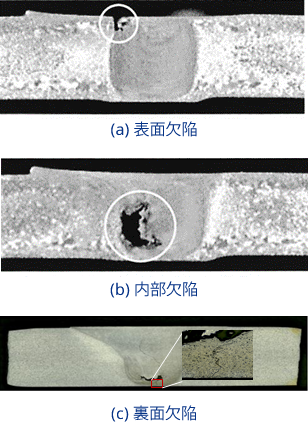

Understood the FSW principle and current challenges

Since the curriculum was tailored to the development content of our company’s product, I acquired immediately useful knowledge. I was able to learn FSW principles linked to quality, and deepen my understanding of the challenges currently occurring. Also, the fact that I was able to study both theory and practical demonstration was very good. This time, I took the introductory course, but I would definitely like to take the intermediate and advanced courses as well.