Adaptive Control System that Connects

Machine Tool CNC and Sensing Devices

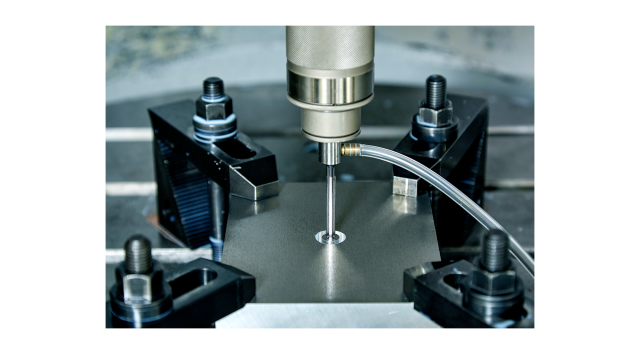

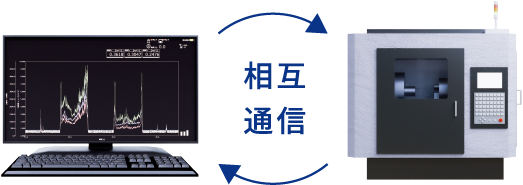

AdvancedControl® is a system for mutual communication between machine tool CNCs, Yamakin’s devices, peripherals, and more.

By combining data from Yamakin’s devices with equipment data, it is possible to create new value and support advanced machining such as stabilizing and improving production efficiency and automation.

Compatible with a wide range of machine tool

CNCs

Sensor and equipment

data collection is possible

Data integration and

threshold control are possible

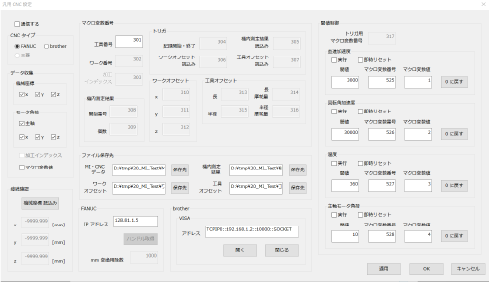

AdvancedControl® can be connected to the machine tool CNC via a PC with a single LAN cable.

01 It is compatible with CNCs from major machine tool manufacturers such as FANUC, Brother, Mitsubishi Electric, and Okuma.

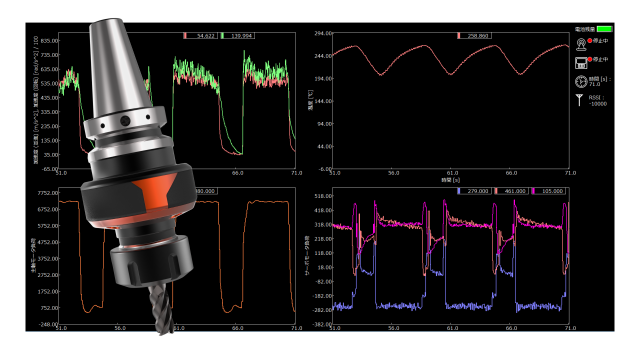

02 In addition to data from Yamakin’s devices, various data from the machine tool CNC (absolute coordinates, spindle speed, each axis servo motor load, macro variables, etc.) can be collected. Data from other sensors and equipment can also be collected as needed.

03 It is also possible to integrate the obtained data and control the operation of the machine tool based on set threshold values.

Specification Details

About Data Collection

▼Collected Data

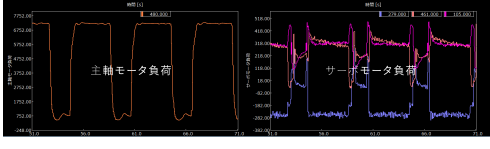

・Machine tool spindle motor load

・Servo motor load

・Absolute coordinate information

・Macro variables

・Data from Yamakin’s devices

・External peripheral equipment information

About Control

▼Controllable Items

・Macro (Common) variable read function

・Automatic data collection

・Data integration

・Threshold control

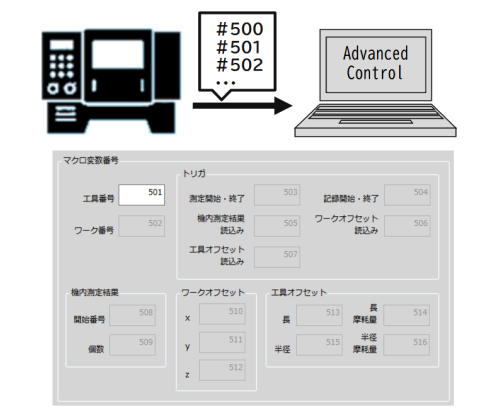

Macro (Common) Variable Read Function

▼Macro (Common) Variable Read Function

Automatic recording and saving of the following data becomes possible:

・Data from Yamakin’s devices

・CNC data

・Value of arbitrary Macro (Common) variables

・Tool offset value

・Workpiece offset value

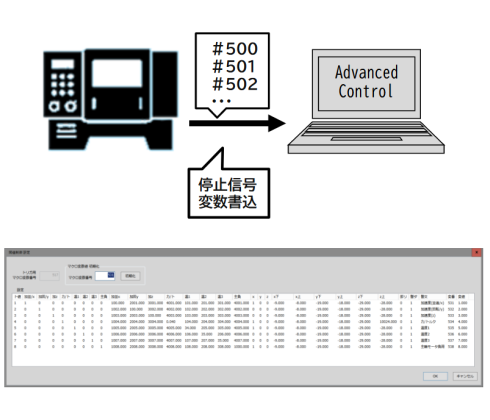

Function to Write Arbitrary Values to Macro (Common) Variables

▼Function to write arbitrary values to macro variables

This function enables threshold control of Yamakin’s device data and CNC data.

・Threshold effective range can be specified with up to 8 conditions (within NC program or coordinate values)

・Control function when threshold is exceeded

→Immediate stop

→Value input to an arbitrary common variable

→Display alarm message on PC monitor

General-Purpose Sensor Synchronization (Option)

▼Examples of General-Purpose Sensors that can be synchronized

・Current measurement by clamp meter

・Analog voltage output sensor, etc.

Compatible Devices and

Compatible CNCs

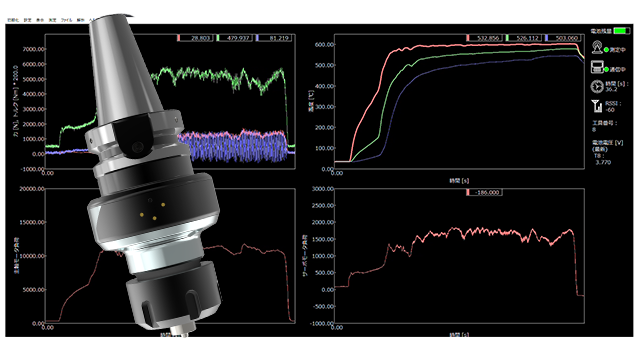

MULTI INTELLIGENCE®ASM

Measures tool temperature in real-time during machining to support optimal machining condition selection and tool life prediction

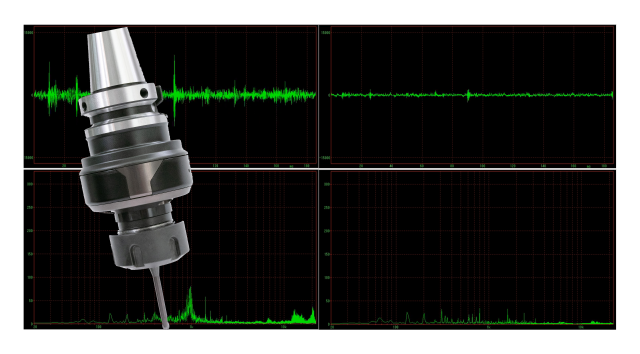

MULTI INTELLIGENCE®i-flash

High-speed sampling of acceleration data enables frequency analysis

High-speed data acquisition reads the true waveform to support the selection of optimal machining conditions

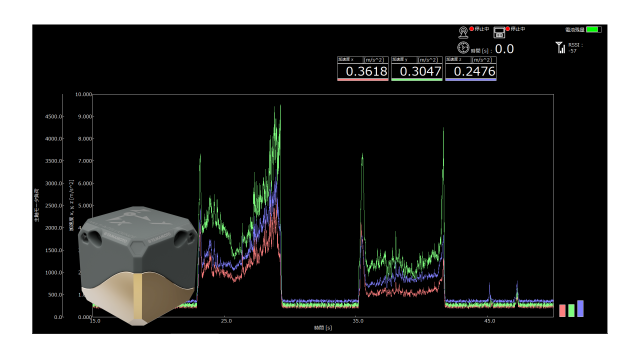

MULTI INTELLIGENCE®b-lex

Measures acceleration in real-time with a box-type device and

can be used in a wide range of applications such as optimal machining condition selection and machine anomaly detection

MULTI INTELLIGENCE®i-stir

Real-time monitoring of tool tip temperature and load data during joining on a PC

Utilized for tool material selection, shape design, and life prediction

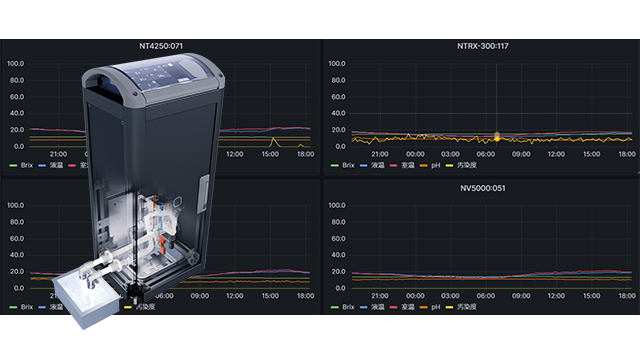

COOL-i® COOLANT ANALYZER

Remotely monitors coolant temperature, concentration, pH, etc., and supports management.

Compatible CNCs

※Even with compatible CNC model numbers, some or all Advanced Control functions may not be supported. Please contact us for details.

| Manufacturer | Model Number |

|---|---|

| FANUC | Series 0i/30i and later (communication may be possible with 16i/18i/21i, etc.) |

| Brother | CNC09.001 and later |

| Mitsubishi Electric | M70,M80 |

| Okuma | OSP-P300 (OSP-API communication option required) |

Implementation Track Record

5axis: 5-axis control machining center MC: Vertical machining center Horizontal MC: Horizontal machining center Gantry MC: Gantry machining center TC: Turning center

In addition to machining centers and turning centers, there are also usage track records with NC grinding machines and press machines.

| Manufacturer | Model Number |

|---|---|

| DMG Mori Seiki | [5axis] NMV5000DCG [5axis] NMV8000DCG [MC] NV5000α |

| FANUC | [MC] RoboDrill α-D21MiB5 |

| Brother | [MC] S500Xd1 [MC] R450X2 |

| Makino Milling Machine | [5axis] a500Z |

| Okuma | [5axis] MU-6300V / [TC] GENOS L25011-e |

| Yasda Precision Tools | [5axis] YBM40 |

| Horkos | [MC] NS70 |

| First Giken | [MC] HAL-K106 |

| Enshu | [MC] [Horizontal MC] |

| Hitachi Power Solutions | [MC] |

| Nachi-Fujikoshi | [MC] |

| Sawai Engineering | [Gantry MC] |

| Hasegawa Machinery | [Horizontal MC] PM150 |

| Takamatsu Machinery | [TC] XW-30 |

| Tsugami | [TC] |

| Takisawa Machine Tool | [TC] TCN-2100 L6 V.EDITION |

| Citizen Machinery | [TC] A20 |

Operating Environment (Required PC Specs)

- CPU: CORE i7 or higher

- Memory: 8GB or more

- OS: Windows 10, Windows 11

- Graphics Board: GTX 1070 or higher

※ Please contact us if you have any questions.

For example, we respond to

requests like these.Request Order

- We want to test the performance of new materials and new products

- We want to know the optimal machining conditions for our manufactured products

- We want to reduce tool costs

- We want to shorten machining time compared to now

- We want to digitize technology that relies on human intuition

- We want to promote smart factory initiatives

Flow until Order / RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the operating environment, etc., through meetings either by visiting or using a web conferencing system.

We will submit a quote based on the specifications.

- Demonstration is also possible

- If you would like to actually try Advanced Control®, a demonstration is possible at the Okayama Research and Development Center or on-site (business trip).

Please feel free to contact us.

- TOP

- Business Introduction

- Machinability Evaluation Testing Service