(Cutting version) Simultaneous Heat and Vibration Measurement Type

Patented, Patent No. 6168695

Real-time measurement of tool temperature during machining

Supports selection of optimal machining conditions and tool life prediction

MULTI INTELLIGENCE® (Cutting version) Simultaneous Heat and Vibration Measurement Type

Patented, Patent No. 6168695

controller, and wireless transceiver

built into the tool holder

recording software

This device enables real-time monitoring of tool temperature and vibration during cutting.

Temperature measurement while applying coolant is also possible (inner-through supported).

It is also possible to measure the temperature of the tool tip during drilling,

which could not be measured with infrared thermography.

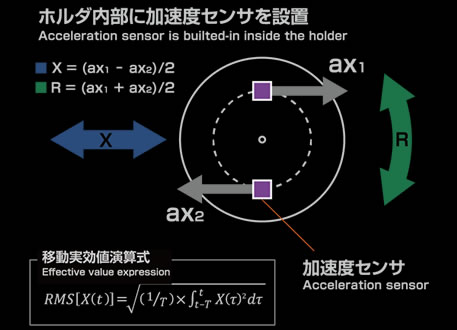

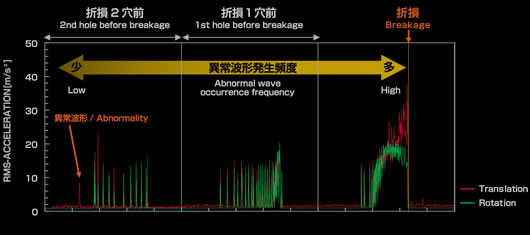

Vibration measurement is possible simply by holding the tool you want to measure,

and monitoring of the process information leading up to breakage is possible.

It also supports small-diameter tools where data detection is difficult.

Realizing the “visualization” of machining phenomena,

it supports the IoT transformation of cutting, optimal machining condition selection, and trouble analysis.

MULTI INTELLIGENCE®

Case StudiesCase

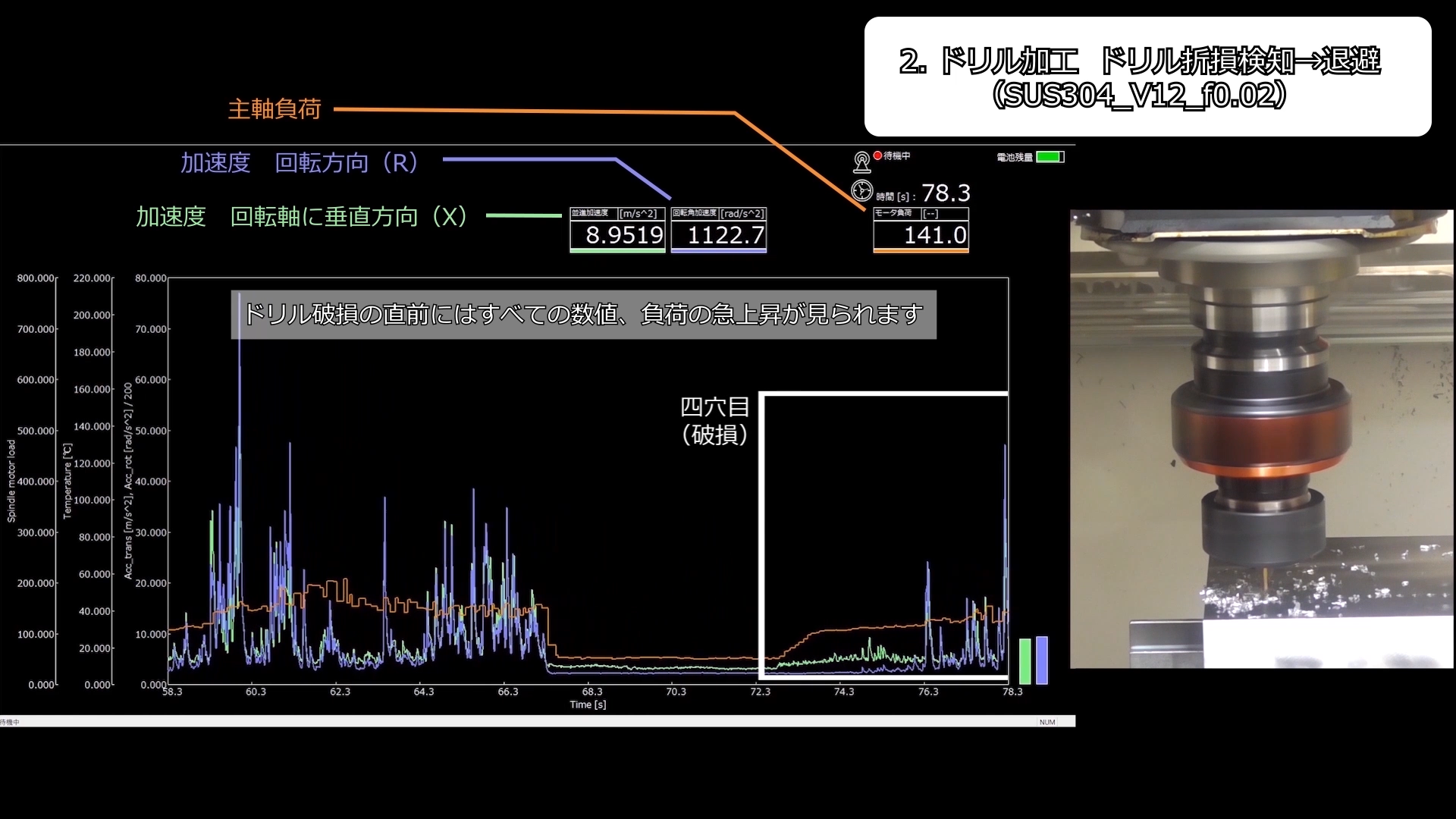

Case 1: Automatic Response After Tool Breakage Detection

Since MULTI INTELLIGENCEⓇ does not detect an increase in acceleration (not exceeding the set threshold) in the next machining step,

it links with the CNC to automatically retract the tool + interrupt the machining process.

Full video available from the link below

https://youtu.be/0CbD1VYjAvk

Customer VoiceCustomer Voice

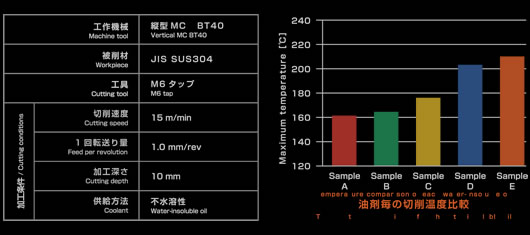

Company A: Responsible for “Technology Development”

Contributes to improving the reliability and sales promotion of developed cutting fluids

While searching for an effective means to evaluate new cutting fluids,

we came across MULTI INTELLIGENCEⓇ from Yamamoto Metal Works Co., Ltd.

Verifying the degree of heat suppression effect the developed fluid has against the heat generated during machining is extremely important for accelerating development speed.

Conventionally, not only was measuring the temperature during machining difficult, but the evaluation methods in actual cutting also differed among manufacturers, and an effective evaluation method for cutting was not established.

By introducing MULTI INTELLIGENCEⓇ, it became possible to evaluate the effect of the developed cutting fluid using the critical parameter of heat.

Furthermore, as the evaluation is the same as actual cutting, it contributes to improving the reliability and sales promotion of the developed cutting fluid.

Rental ServiceRental

We solve these kinds of problems

I want to know better conditions

than the current machining conditions

I want to know the machinability of new tools

I want to know the machinability of new materials

I want to know the performance of new cutting fluids

MULTI INTELLIGENCE® is also available for rent.

If you are wondering what it can do, please check the performance of MULTI INTELLIGENCE® through our rental service.

- ● The items for rent are those shown in the photo below. *Please prepare your own PC.

- ● Available for rent starting from 1 week.

- ● MULTI INTELLIGENCE® can also be utilized for outsourced testing.

Rental Equipment

- Specified ASM Holder

- Transceiver

- Software Dongle Key (USB)

- Dedicated Charger

*Please prepare your own PC

Frequently Asked QuestionsFAQ

We have compiled frequently asked questions from everyone.

We welcome questions other than those listed below, so please feel free to contact us.

- What can it do? Are there any specific examples?

- Real-time monitoring of temperature and vibration during machining is possible.

It is effective for tool life determination, anomaly detection, and optimization of cutting conditions.

- What is the structure of MULTI INTELLIGENCE®?

- It is a rotating tool holder used in machining centers.

It has built-in temperature sensor, acceleration sensor, electronic circuit, and wireless transmitter.

- Who should I contact if it breaks down? Is there a charge?

- Please contact a Yamamoto Metal sales representative. If you have an annual maintenance contract, repairs will generally be performed free of charge.

However, please note that damage caused by modification by your company or use that is different from the intended purpose is not covered under warranty.

Thermocouple breakage is treated as a consumable item each time.

- How is the setup done? Is it easy?

- Except for the temperature and vibration monitoring function, it is a rotating tool holder used in machining centers, so please attach the tool according to the chuck type.

When monitoring temperature, a hole for inserting the temperature sensor is required on the tool side.

Since it is a dedicated sensor, please provide us with information about the tool you will be using and

the position where the sensor will be inserted.

Also, tools into which a temperature sensor can be inserted are basically solid-type tools, and

a core thickness of φ2.5 or more is recommended.

For tools that do not meet this requirement, please consult with us, and

we will consider its applicability.

- Can any collet be attached?

- We use ER standard collets.

The collet sizes are ER25, ER32, and ER40.

- Can we prepare the monitoring PC ourselves?

- Basically, the customer is asked to prepare it. We can provide one upon request.

- How long does the battery last on a single charge? And how much charging time is required?

- It depends on the sampling rate, but for the i-flash model, it is about 2 hours.

- How many MPa is possible for high-pressure coolant?

- Up to 7MPa is possible.

Basic SpecificationsSpecification

Tool Holder

| Shank Standard | BT30,BT40,BT50,HSK63A,HSK100A *Other than basic specifications are also possible (consultation required) |

|---|---|

| Chuck Type | See figure below *Consultation is also accepted for standards other than those in the compatibility table |

| Maximum Tool Insertion Depth | 39mm |

| Maximum Rotational Speed |

BT30,BT40,HSK63A:20,000rpm BT50,HSK100A:10,000rpm |

| Rotational Balance | 1.2g・mm or less |

| Others | Rechargeable, External and Internal Coolant Supply Possible (7Mpa) |

*1 Compatibility Table

ER: Taper Collet, 16° taper compliant with standard DIN6499/ISO15488

ER: Taper Collet, 16° taper compliant with standard DIN6499/ISO15488

SL: Side Lock

FM: Face Mill Arbor

Sensor Unit

| Common | Power Source | 3.7V Lithium-ion rechargeable battery (Built into the unit) |

|---|---|---|

| Continuous Operating Time | 24H or more *May be shorter depending on usage conditions and environment |

|

| Charging Time | Max. approx. 2.5H | |

| Sampling Rate | Approx. 100ms(10Hz) | |

| Operating Radio Frequency Band | 2.4GHz band | |

| Communication Range | Approximately 20m or less (without obstructions) | |

| Temperature | Number of Measurement Points | 1 point (Can be specified on the tool rotation axis) |

| Sensor Type | φ0.5 Sheath Thermocouple K-type (JIS Class 2 equivalent) *Thermocouples other than φ0.5 are also possible (consultation required) |

|

| Temperature Measurement Range | 0~1000℃ | |

| Acceleration | Detection Direction | Perpendicular to the rotation axis [X], Rotation axis direction [R] |

| Input Range |

X direction: 3~600m/s2 R direction: 600~12,000rad/s2 |

|

| Detectable Frequency Range | 0~6,000Hz (Detection range of piezoelectric sensor) | |

| Evaluation Index | Effective value m/s2 (Integration time approximately 100ms) |

Product LineupLINEUP

MULTI INTELLIGENCE®

(Cutting version)

Simultaneous Heat and Vibration Measurement Type

This device enables real-time monitoring of tool temperature and vibration during cutting. Temperature measurement while applying coolant is also possible (inner-through possible). Vibration measurement is possible simply by holding the tool.

MULTI INTELLIGENCE®

(Cutting version)

i-flash Cutting Vibration Measurement Type

High-speed sampling of acceleration data enables frequency analysis. (Sampling rate 44.1kHz)

Reads the true waveform through high-speed data collection and supports the selection of optimal machining conditions.

*Only supported for Machinability Evaluation Test Service and Rental Service

For example, we can meet

these kinds of requests.Request Order

- I want to “visualize” the phenomena during machining

- I want to measure the temperature of the tool tip while applying coolant

- I want to find machining conditions that can suppress chatter

- I want to find the cause of machining failure

- I want to detect internal material defects and prevent machining troubles

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will hold a meeting through a visit or a web conferencing system.

It is also possible to observe in advance what kind of monitoring device MULTI INTELLIGENCE® is.

- Machinability Evaluation Test Service is also available

- You can also request an evaluation utilizing MULTI INTELLIGENCE® through the Machinability Evaluation Test Service.

We support the selection of optimal machining conditions through the “visualization” of machining phenomena.

- TOP

- Product Information

- MULTI INTELLIGENCE®

- (Cutting version) Simultaneous Heat and Vibration Measurement Type