What is Resin?

The original meaning of resin refers to a substance formed when tree sap solidifies.

Generally, the image of **plastic** is strong, but it can be broadly divided into **natural resin** and **synthetic resin**.

Famous natural resins include pine resin and lacquer, which are materials found in nature. Synthetic resins are fossil resources like petroleum, coal, and natural gas that are processed by humans,

and famous examples include plastic, polyethylene, and polyvinyl chloride.

Since their resin physical properties and resin mechanical characteristics differ, it is necessary to investigate the resin properties for production and research.

On this page, we introduce methods for measuring the durability, processability, and fatigue of products and materials made from such resins.

Properties of Resin (Plastic)

| Rigidity | Weight | Electrical Insulation | Chemical Resistance | Appearance | Moldability | Productivity | Environmental Aspects | Others |

|---|---|---|---|---|---|---|---|---|

| Wide range of properties – from soft to hard | Low specific gravity | Good | Some are strong, but some are weak against chemicals | Some are colorless and transparent, coloring is also possible | Good | Low-cost and short-time production possible | Easy to recycle | Some have good sliding properties and are often used for gears in industrial machinery |

| Heat Resistance | Durability | Surface Hardness | Thermal Conductivity | Static Electricity |

|---|---|---|---|---|

| Low – easy to deform | High degree of age deterioration | Low | Low | Prone to static discharge – easily soiled |

Comparison of Resin and Metal

| Material | Specific Gravity | Tensile Strength (kg/㎟) | Specific Tensile Strength (kg/㎟) | Charpy Impact Value (kg-cm/㎟) |

|---|---|---|---|---|

| Glass cloth filled polyester molded product | 1.7 | 40.8 | 24.0 | 1.38 |

| DAP glass cloth filled molded product | 1.7 | 33~45 | 19.4~26.5 | 1~1.4 |

| Epoxy resin metal fiber filled product | 1.8 | 33.5 | 18.6 | – |

| Phenol glass cloth filled product | 1.8~2.0 | 15~20 | 14.3~14.6 | 0.8~0.9 |

| Nylon 6 | 1.09~1.14 | 4.9~7.7 | 4.4~6.9 | 0.054 |

| Rigid Polyvinyl Chloride Resin | 1.35~1.45 | 3.5~6.3 | 2.5~2.4 | 0.02~0.05 |

| Duralumin | 2.8 | 38~44 | 13.6~15.7 | 2~4 |

| Aluminum | 2.7 | 7~11 | 2.6~4.1 | 6~9 |

| Hard Steel | 7.85 | 58~70 | 7.4~8.9 | 4 |

| Wood (Laminated Wood) | 1.3~1.4 | 19~20 | 1.43~14.6 | 0.8~0.9 |

Possible to measure and evaluate resin materials (plastics) with **”Measurement and Evaluation Technology”**

Characteristics are opaque because it’s a new material

I know investigation is necessary but lack equipment and expertise

Shortage of staff, machinery, and time for evaluation testing

Currently, the use of resin materials is increasing due to the spread of 3D printers.

Moreover, they are cheaper than metal materials and their shape can be freely changed.

Consequently, new materials with various properties are born every day.

However, what are the properties of these new materials??

There are many types and options. Have you established clear criteria for judgment??

Yamamoto Kinzoku Seisakusho’s “Measurement and Evaluation Technology” can evaluate such resin materials!!

Resin Material

Evaluation and Measurement Methods

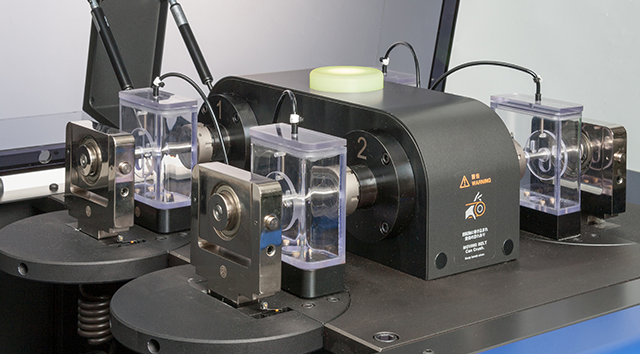

Rotary Bending Fatigue Test Service

Consult us for everything from creating resin test pieces to the rotary bending fatigue test!

High-Precision Internal Residual Stress Measurement Method MIRS®

This is an extremely simple measurement method that derives residual stress from the change in hole diameter before and after stress release by trepanning.

It allows the measurement of residual stress in resin materials, which is difficult to measure with X-rays.

YAMAMOTO’s core technologies (precision machining/measurement technology), cultivated since its founding, such as precisely drilling holes and accurately measuring diameters, are utilized.

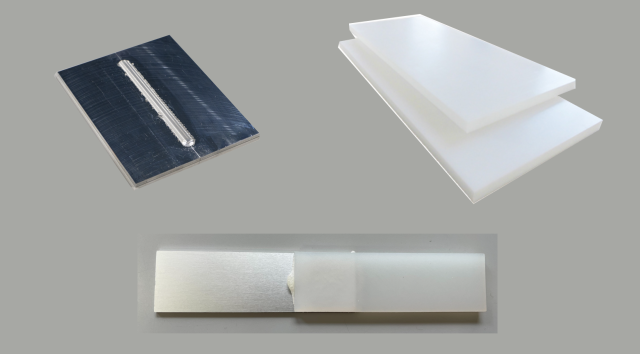

FSW Evaluation Test Service

In addition to joining and cutting evaluation of light metals, we can also handle tests for materials that are difficult to join by friction stir welding or difficult to cut, such as CFRP and resin.

Machinability Evaluation Test Service

By conducting quantitative analysis instead of relying on the intuition of experienced personnel to compare machinability with conventional methods, you can achieve reliable reductions in processing time, quality improvements, and R&D.

Tool wear, cutting resistance, temperature and vibration during cutting, and surface roughness of resin and metal can be “visualized” with data.

For example, we respond to these requests.Request Order

- A new resin material was created, but its functional properties are unknown

- I want to efficiently develop new resin materials

- I want to use resin (plastic) as a new component, but the fatigue strength is unknown

- I want to accurately investigate the internal residual stress distribution of resin materials

Flow from Order to RequestFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the test specifications through a visit or a web conferencing system meeting.

We will submit a quotation based on the test specifications.

- Witnessing the test is possible

- If you actually place an order, witnessing the test is possible.

Please feel free to contact us.

- TOP

- Business Introduction

- FSW Evaluation Test Service