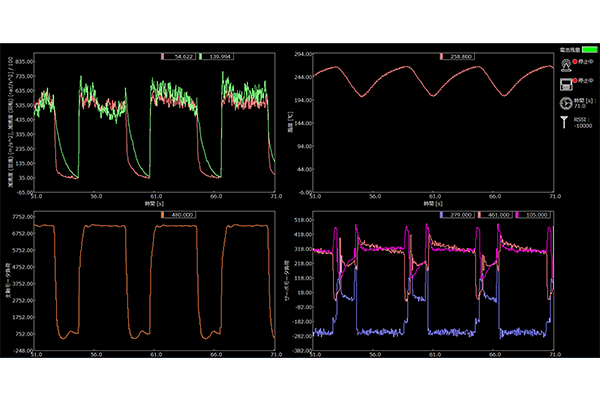

inside the tool during cutting

Since sensors (thermocouples, etc.) are built-in near the tip of the cutting tool/tool pin,

it is possible to measure the temperature and vibration at the tool edge/pin tip.

We support the IoT transformation of cutting/joining and the selection of optimal machining conditions.

We “intelligize” the tool itself and realize the “visualization” of machining/joining phenomena.