リアルタイムに測定可能

MULTI INTELLIGENCE®i-stirについてFSWモニタリングデバイス

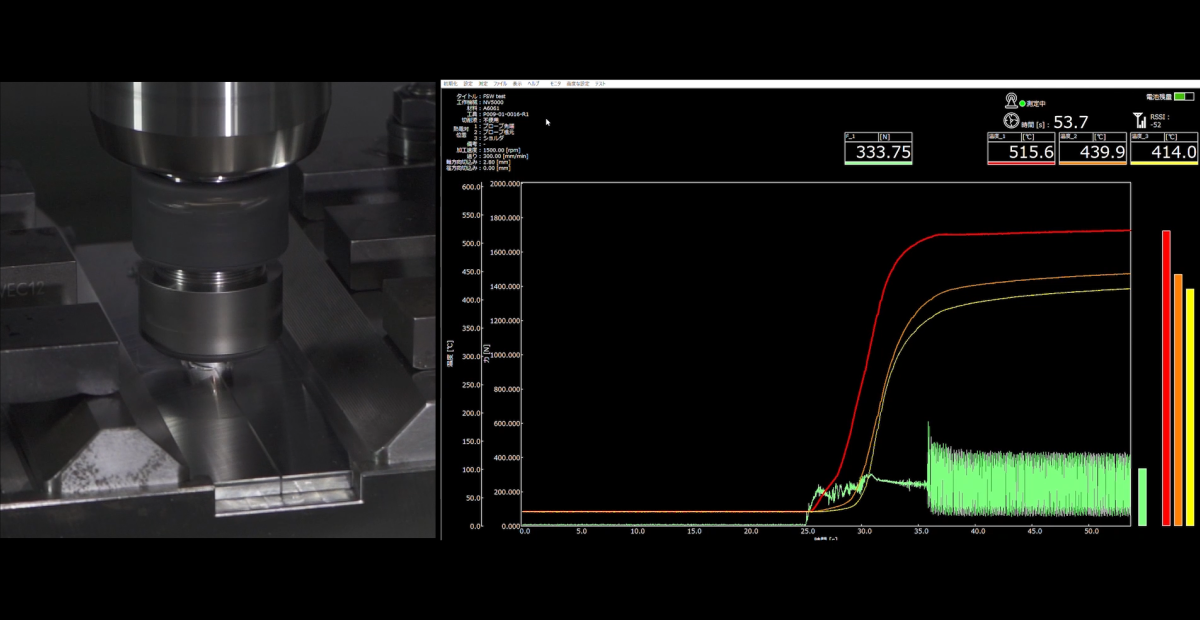

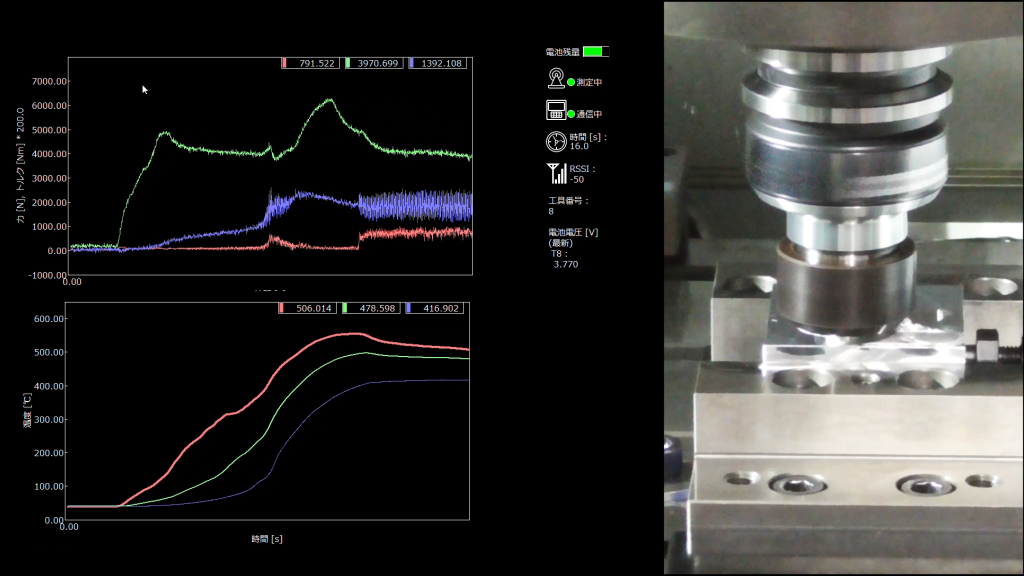

接合中のツール先端温度と負荷データをPC上でリアルタイムモニタリング

ツールの材質選定、形状設計、寿命予測に活用

摩擦攪拌接合(FSW)における接合中のツールの温度や力をリアルタイムにモニタリングする事が可能なデバイスです。

接合条件や母材の違いによる温度変化、負荷の変化を把握することが可能なので、良好な接合が行われているかの判断材料になり、

接合品質の向上、接合不良の原因判別、接合条件の良否判定につながります。

現在ご使用のマシニングセンタでそのまま使用が可能で、FSWを始めてみたいといったニーズにもこたえることができます。

様々な使い道があり、接合、試験、教育(トレーニング)にもご使用いただけます。

販売・レンタルだけでなく受託試験サービスも展開しておりますので是非ご活用くださいませ。

リアルタイムに測定可能

承っております

温度の読み取り・記録が可能

摩擦攪拌接合(FSW)における接合中のツールピンの先端温度をPC上でリアルタイムにモニタリングする事が可能な機器です。

(インナースルー不可)

摩擦攪拌接合(FSW)のIot化・最適接合条件選定・品質評価を

サポート致します。

工具そのものを”知能化”し接合現象の”見える化”を実現します!!

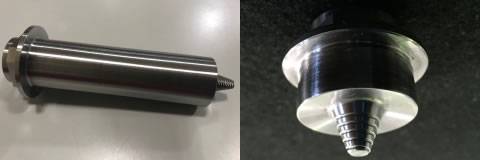

ツールピンの先端付近に温度センサ(熱電対)を内蔵しているため、接合中の先端温度を測定する事が可能です。

加工技術・計測評価技術を活かし、ツールピンの温度計測が可能なFSW用ツールの製作も承っております。最適な摩擦撹拌接合の条件の導出にはツールピンの温度の測定は必要です。

山本金属製作所では接合材料・用途に応じたツールの材質・形状の提案もさせて頂きます。

ツール材質実績:SKD・超鋼・セラミックス・Ni基合金・コバルト合金・タングステンカーバイド等

ホルダー内部に熱電対とひずみゲージ、ワイヤレストランスミッターを搭載。

計測した温度と力情報は無線送信されPCモニタで確認する事が可能です。

接合事例Movie

・同材種接合例:各種アルミ合金(A6061, A6063, A5052, A7075, ADC12, AC4C等)、銅

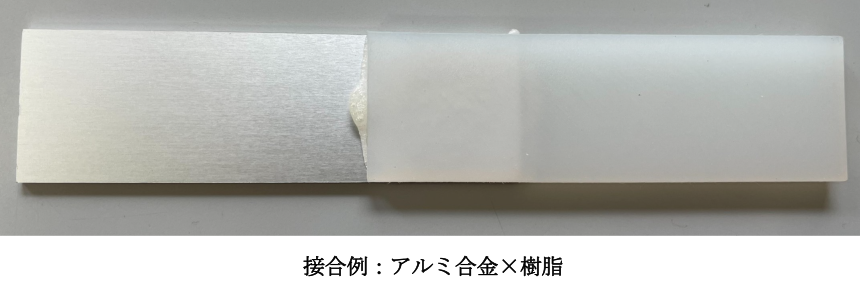

・異材種接合例:アルミ展伸材/アルミ鋳物、アルミ/鋼、アルミ/銅、アルミ/樹脂

FSW最適生産ソリューションサービスFSW solution service

こんなお悩みを解決します

現状の接合条件より

良い条件を知りたい

プローブの磨耗が激しく工具費用が大きな負担になる

接合メカニズムが解明されていない・効率の良い試験計画が組み立てれない

実技演習を伴ったFSWの接合理論を学べる場が少ない

弊社ではFSW最適生産ソリューションサービスとしてMULTI INTELLIGENCE®FSWverを活用しお客様のお悩みを解決致します。

教育・評価試験・レンタルサービスを取り扱っておりますのでお気軽にお声掛けくださいませ。

- ● レンタルする物品は計測機本体とPC(ソフトインストール済)となります。

- ● 1週間からレンタル可能です。

- ● MULTI INTELLIGENCE®は受託試験でも活用頂けます。

よくある質問FAQ

皆様からよく頂く御質問をまとめました。

下記以外の質問もお待ちしておりますので、是非お問い合わせ下さい。

- ツール形状を変更したい場合は?

- ツールは弊社からご購入いただきます。

弊社にご依頼いただければユーザー様の希望の形状で製作しいたします。

- FSWツールを交換した場合、熱電対は再利用できますか?

- 再利用はできません。

- 使用最高回転数は?

- 最高20,000回転/分です。(BT50,HSK100Aは10,000回転まで)

- 無線通信可能距離は?

- 安定して受信可能な距離として、20mを想定しておりますが、使用環境によっては大きく変動します。

- 連続使用可能時間は?

- 6時間ほどです。

- 主軸ツールの電源用電池は?

- 1/2AAサイズ(単三乾電池の半分の長さ)の塩化チオニルリチウム電池で、

公称電圧が3.6Vの製品です。

- 測定できる最高温度は?

- 標準の熱電対シース太さ(φ1.0)の場合、

連続使用温度は標準品・特注品いずれも600℃となります。(JIS規格での規定)

なお、瞬間的な昇温に対しては、

シース太さ(φ1.0)の標準品で650℃、特注品で1000℃となります。

ただし、基板内部温度が60℃以下であることが条件です。

- 防水ですか?

- IP×5~6程度の防水機能があります。

- モニター用パソコンは自社で準備してもよいか?

- 基本的にお客様にご準備いただく形になります。ご要望があれば弊社で用意させていただきます。

- 最大でいくらの厚みまで対応可能か?

- 軽金属(アルミ合金、マグネシウム合金等)で最大10mmとなります。

- 鉄系素材の接合にも対応可能か?

- 材種や板厚によっては対応可能です。

- サンプリングレートは?

- 最大サンプリングレートで0.1秒ごととなります。

製品ラインナップLINEUP

MULTI INTELLIGENCE®

(Cutting version)

熱・振動同時計測type

切削加工時の工具の温度・振動をリアルタイムにモニタリングする事が可能な機器です。クーラントを掛けながらの温度計測も可能(インナースルー可)・振動を計測については工具を把持するだけで可能です。

MULTI INTELLIGENCE®

(Cutting version)

i-flash 切削振動測定type

加速度データの高速サンプリングにより、周波数解析が可能です。(サンプリングレート44.1kHz)

高速データ収集で真の波形を読み取り最適加工条件の選定をサポート。

※被削性評価試験サービス・レンタルサービスのみ対応

例えば、このような

ご要望にお応えします。Request Order

- FSW(摩擦攪拌接合)について社内で採用実績がなく、前例もないので、試験のとっかかりが難しい

- 新素材や新形状に対しての、適切なツールと接合条件等が分からない

- 接合メカニズムが解明されていない効率の良い試験計画が組み立てれない

ご注文・ご依頼までの流れFlow

- お電話・メールで、ご相談を受け付けます

- まずは、お電話またはメールでお気軽にお問い合わせください。

スピーディーにご対応させていただきます。

- ヒアリングし、お客様のご要望をお伺いします

- お客様の設計図面をお送りいただき、お客様の要望を詳細にお伺いします。

加工可能かを判断のうえ、お見積りをご提出し、納期をお伝えします。

- ご希望に応じて、加工を熟知した担当者が訪問いたします

- ご希望により、当社の担当者がお客様のもとへお伺いします。

(但し、地域等により訪問できない場合もあります)

貴社にとってベストな製品につながるご提案をさせていただきます。

- TOP

- 製品情報

- MULTI INTELLIGENCE®

- (FSW version)