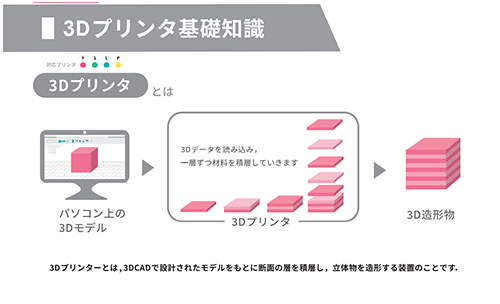

Types and Features of 3D Printers

A 3D printer is a device that creates a three-dimensional object by stacking cross-sectional layers one by one based on a 3D model designed on a PC.

The types of 3D printers include FDM (Fused Deposition Modeling), SLA (Stereo Lithography Apparatus), LAM (Liquid Additive Manufacturing), and PBF (Powder Bed Fusion). FDM is a method where a filament-shaped resin is melted by heat, extruded from a nozzle, and the resin is stacked like a single stroke to form the object. SLA is a method of forming a model by hardening photo-curable resin by irradiating it with an ultraviolet laser. It allows for the creation of thin-walled parts and grooves that cannot be reproduced by cutting processes. The PBF method is the most common metal 3D printing method, where small spherical metal powder is spread out, irradiated with a laser or other means to melt and solidify it.

If you want to know more about 3D printers, please download the PDF document here.

3D Printer

Solution Service

Optimal Design

Modeling suited to the fabrication method

Pursuit of post-machinability using machine tools

Prototype Fabrication

Speedy prototype fabrication possible

using our in-house 3D printers

Prototype Evaluation

Evaluation of strength, durability, and

post-machinability of layered prototypes

In recent years, the technological development of 3D printers has been remarkable, and they are being used in various fields.

As long as there is a 3D model, the imagined object can be fabricated, establishing 3D printing as a new option in manufacturing.

Yamamoto Kinzoku researches and operates this 3D printer technology in-house, and offers a 3D Printer Solution Service that leverages its core machining technology and robot SIer expertise.

What is the 3D Printer Solution Service?

Yamamoto Kinzoku offers four services utilizing 3D printers:

・Prototype Fabrication ・Small-Lot Product Production (including prototypes) ・Prototype Evaluation ・Prototype Design Support.

We hope that you will learn how to utilize 3D printers, which are rapidly spreading globally, and that this service will be useful for future equipment introduction and further technological advancement.

Prototype Fabrication

We fabricate models designed by customers using the various 3D printers owned by Yamamoto Kinzoku.

We discuss conditions such as material, size, and precision, and propose the optimal printer for fabrication.

Manufacturing utilizing 3D printers allows for a quick cycle of prototyping → evaluation → improvement, achieving an overwhelmingly efficient product development cycle.

Yamamoto Kinzoku has realized medical device development in a short period of six months by accelerating this development cycle.

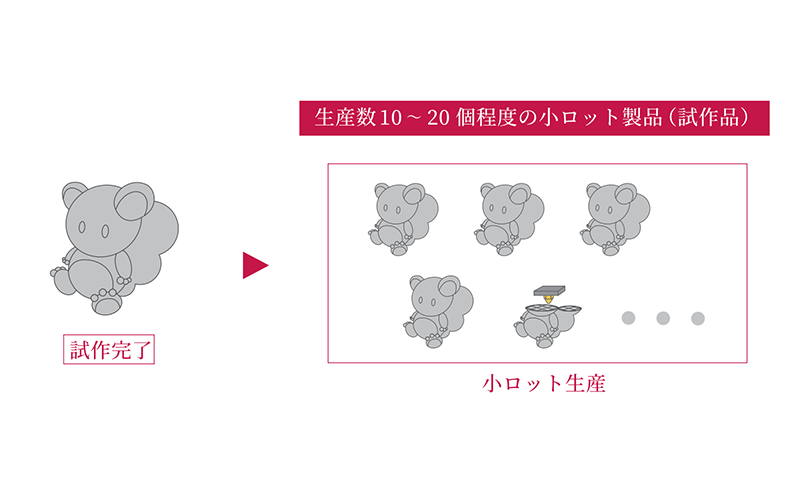

Small-Lot Product Production (including prototypes)

We conduct small-lot production of actual products or equivalent prototypes.

While we primarily propose high-strength resin materials,

we also support fabrication using soft resin or silicone rubber according to the application.

Prototype Evaluation

We conduct evaluations of the strength, durability, and post-machinability of layered prototypes.

Our material evaluation service, which Yamamoto Kinzoku excels at, supports appropriate material selection and design.

Click here for details on Rotary Bending Fatigue Testing

Click here for details on Residual Stress Measurement Solution Service

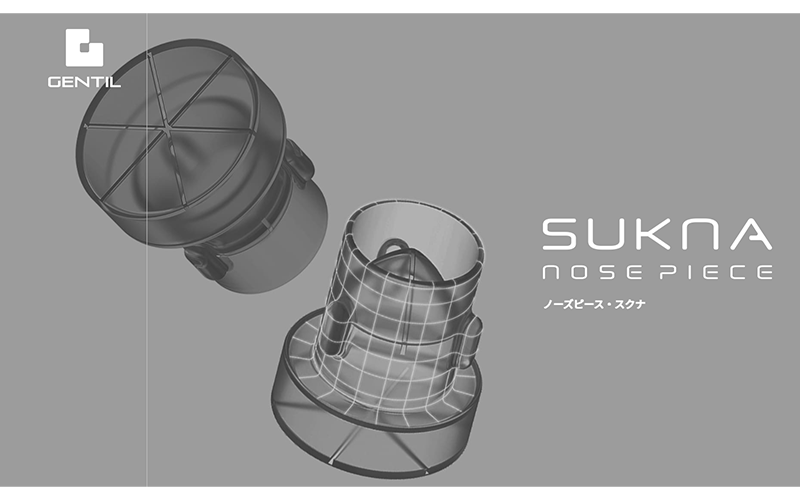

Prototype Design Support

We provide design support for modeling based on the premise of production by a 3D printer,

and for modeling that takes into account post-machining by cutting after fabrication.

You will repeatedly experience prototyping and evaluation using an actual 3D printer.

Example responses: I want to make it lighter than conventional products. I want to improve durability. …etc

Examples of 3D Printer Utilization

Improved Design of a Robot Arm

Optimal design using Generative Design was implemented to achieve stable movement of the workpiece (higher speed) and improved safety through weight reduction.

Generative Design was used to set parameters such as function, spatial conditions, material, and manufacturing method to find the optimal shape, which was then fabricated using a 3D printer.

This resulted in an ideal design that pursues both functionality and productivity, which is difficult to achieve with general design methods.

This is an example where a consistent process design up to the goal became possible, thanks to Yamamoto Kinzoku’s expertise gained from pursuing machining, including equipment design capability, tool selection, dedicated jig design, and setting conditions for various materials, combined with its expertise in structural optimization and 3D fabrication.

※Generative Design is a type of design exploration process that sets parameters such as function, spatial information, material, and manufacturing method to find and generate possible solutions.

Evaluation and Measurement Methods for Metal Additive Manufacturing Materials

GIGAQUAD® – Four-Station Rotary Bending Fatigue Testing Machine –

GIGAQUAD® is a rotary bending fatigue testing machine that achieves efficient and very high reproducibility through the adoption of a four-station system. By simultaneously testing four test pieces under their respective conditions, data collection is fast, and efficient S-N curve creation is possible.

We offer a consistent service from the production of GIGAQUAD® test pieces to contract testing.

Furthermore, the after-sales service is also comprehensive, including regular maintenance and overhaul services, ensuring a safer user experience.

MIRS® – High-Precision Internal Residual Stress Measurement Method –

This is an extremely simple measurement method that derives “residual stress”—one of the causes of stress corrosion cracking, reduction in fatigue strength, and brittle fracture in various processed components—from the change in hole diameter before and after stress release by trepanning. YAMAMOTO’s core technologies (precision machining/measurement technology), cultivated since its founding, such as precisely drilling holes and accurately measuring diameters, are utilized.

List of Owned 3D Printers

- Markforged MARK TWO Fused Deposition Modeling (FDM)

- Kyuhou Kinzoku Seisakusho Qholia Material Extrusion Deposition (FDM)

- formlabs Form3 Stereolithography (SLA)

- German RepRap L320 Liquid Additive Manufacturing (LAM)

- German RepRap x500pro Fused Deposition Modeling (FDM)

Available Processes

- Plating

- Painting

- Blackening

- Blasting

- Shot Peening

- Heat Treatment etc

- PFAS (Teflon) Free Coating

※We can offer PFAS-free coating that achieves low friction and high durability without using PFAS (Teflon), which is a source of environmental concern.

Flow from Order to Request

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate the test specifications through a visit or a web conferencing system meeting.

We will submit a quotation based on the test specifications.

- Our representative, knowledgeable in 3D printers, will visit upon request

- Upon request, our representative will visit your location.

(However, visits may not be possible depending on the region, etc.)

We will propose the best solution for your product.

- TOP

- Business Introduction

- 3D Printer Solution Service