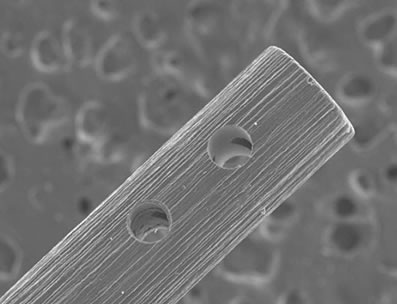

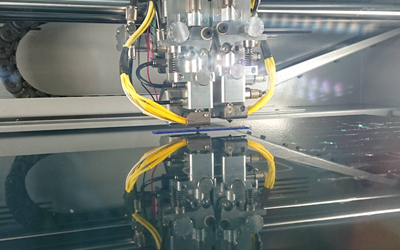

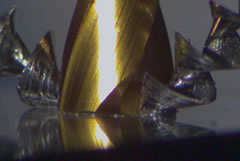

By incorporating the know-how gained from our unique **machining monitoring technology**, we also derive optimal machining conditions and develop tools. This allows us to achieve process integration and reduced machining time, and finish **micro-machining** and **complex shapes**—often deemed impossible—with high quality and high precision. Additionally, shapes like impellers that are difficult with 3-axis machining can be handled with simultaneous 5-axis control machining.

Precision Machining Technology Pursued Since Our Founding

From Prototyping and Modeling to Mass Production Machining

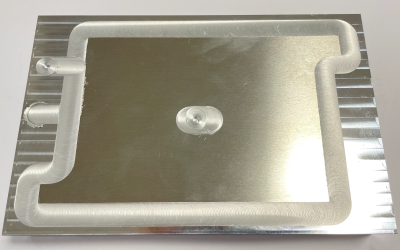

Hydraulic Equipment Parts

Medical Device Parts

Machine Tool Parts

Energy Infrastructure Parts

Motorcycle Parts

Semiconductor Equipment Parts

Since our founding, we have been committed to advancing “technology for cutting, polishing, and drilling metal,”

and have enhanced our precision machining technology.

We deliver reliable products through a production management system capable of integrated orders for high-mix, low-volume to mass production machining,

and well-equipped machining facilities.

We cater to a wide range of fields including **hydraulic equipment parts, medical device parts, machine tool parts, and energy infrastructure parts**.

Reliable Quality Assurance System

Backed by High Technology and

Years of Experience

The requests from our customers are all essential for a “safe and secure” society.

We deliver the best products with a perfect quality assurance system.

In addition to in-process inspections by the staff in charge, we perform inspections using the latest measuring instruments,

and manage precision at each stage.

Geometric Tolerances are Measured

We measure and inspect all machined surfaces using a **CMM (Coordinate Measuring Machine)**, **roundness measuring instrument**, **surface roughness tester**, **universal projector**, etc. We measure the **dimensional accuracy** and **geometric tolerances** of all products listed in the design drawings down to the **micron level**, and deliver them with complete assurance of precision. Furthermore, we conduct particularly strict measurements on products machined during time slots when precision is prone to variation to maintain quality.

on Inspection Certificate for All Products

The measurement data of machined parts is recorded on an **inspection certificate** for each item and attached upon delivery. We guarantee the highest level of quality. Upon customer request, **100% inspection** can be performed, and measurement data can be submitted. Moreover, these data histories are recorded and managed in our internal database, allowing for **traceability confirmation**.

Main National Certification Holders (Only 1st Grade equivalents listed)

| Certification Name | Grade / Level | Number of People |

|---|---|---|

| National Trade Skill Test: Machining | Master Grade Skill Technician | 14 |

| National Trade Skill Test: Numerical Control Lathe | 1st Grade Skill Technician | 22 |

| National Trade Skill Test: Numerical Control Milling Machine | 1st Grade Skill Technician | 27 |

| National Trade Skill Test: Machining Center | 1st Grade Skill Technician | 5 |

| National Trade Skill Test: Milling Machine | 1st Grade Skill Technician | 1 |

| National Trade Skill Test: Electronic Equipment Assembly (Electronic Device Assembly Work) | 1st Grade Skill Technician | 1 |

| National Trade Skill Test: Machine Inspection | Master Grade Skill Technician | 2 |

| National Trade Skill Test: Machine Inspection | 1st Grade Skill Technician | 1 |

| Certification Test: Material Testing Engineer (Fatigue Testing) | 1st Grade Skill Technician | 2 |

| National Trade Skill Test: Machine Inspection Work | 1st Grade Skill Technician | 4 |

| Certification Test: Non-Destructive Testing Engineer (Penetrant Testing) | Level 1 | 2 |

| National Test: Information Processing Technician | Applied Information Technology Engineer Examination | 1 |

For example, we respond to these kinds of

requests.Request Order

- Want to quickly confirm the performance of a prototype for new product development

- Need to complete a prototype as soon as possible

- Other companies refused because the delivery time is short

- Other companies refused due to required precision or complex shape

- The precision of the previous contractor has dropped

- Currently using another company but looking for a new outsourced machining company, etc.

Flow until Order/RequestFlow

- Consultations accepted by phone or email

- Please feel free to contact us by phone or email first.

We will respond quickly.

- We will conduct a hearing and listen to customer requests

- Please send us your design drawings, and we will listen to your requests in detail.

After assessing feasibility, we will submit a quotation and inform you of the delivery time.

- A representative knowledgeable about machining will visit upon request

- Upon request, our representative will visit your location.

(However, visits may not be possible depending on the region, etc.)

We will propose solutions that lead to the best product for your company.

- TOP

- Business Introduction

- Machining Technology