in real-time during machining

Free choice of installation location

This device is capable of monitoring all types of vibrations in real-time.

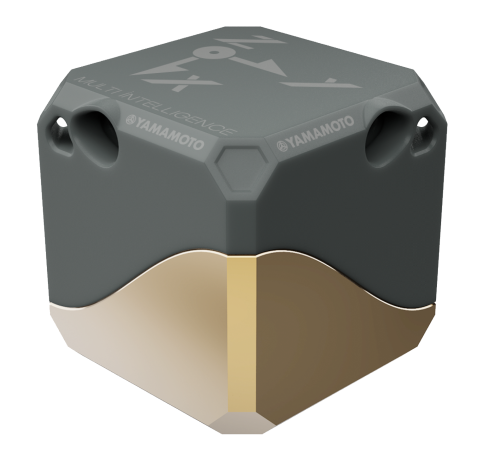

With a compact size of 25×25×25 [mm], it can be installed anywhere and measures vibration at any desired location.

Since it has a waterproof function, it can be used in environments affected by coolant or water.

A wireless transceiver is built into the main unit, making it easy to use.

Realizing the “visualization” of acceleration phenomena,

it supports optimal machining condition selection and trouble analysis.

| Power Supply Method | Battery or Wired Power Supply |

|---|---|

| Mounting Method | Magnet or Bolt Fastening |

| Sampling Rate | MAX 200Hz |

| Size |

25×25×25【mm】 |

| Acceleration | Detection Direction | Orthogonal 3-axis direction (X, Y, Z) |

|---|---|---|

| Calculation Method |

RMS (Root Mean Square) |

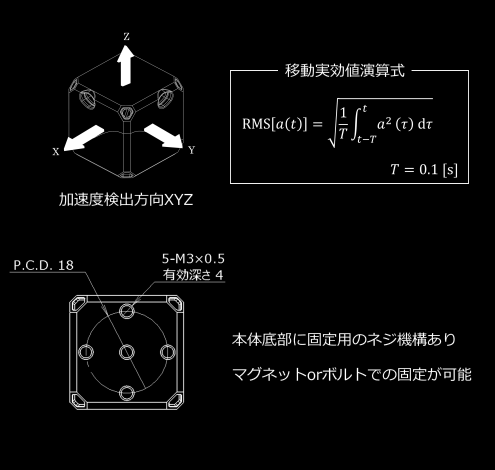

MULTI INTELLIGENCEⓇ b-lex installed in the middle section of the impeller.

It visualized chatter and overload during blade machining.

This visualization allowed for early detection of areas needing correction and

made it possible to consider machining path corrections based on acceleration and spindle load data.

*Spindle load can be acquired with Advanced Control®.

What is Advanced Control®?

It is a machine tool CNC control system that utilizes various sensing data acquired by our devices and data from the machine tool itself.

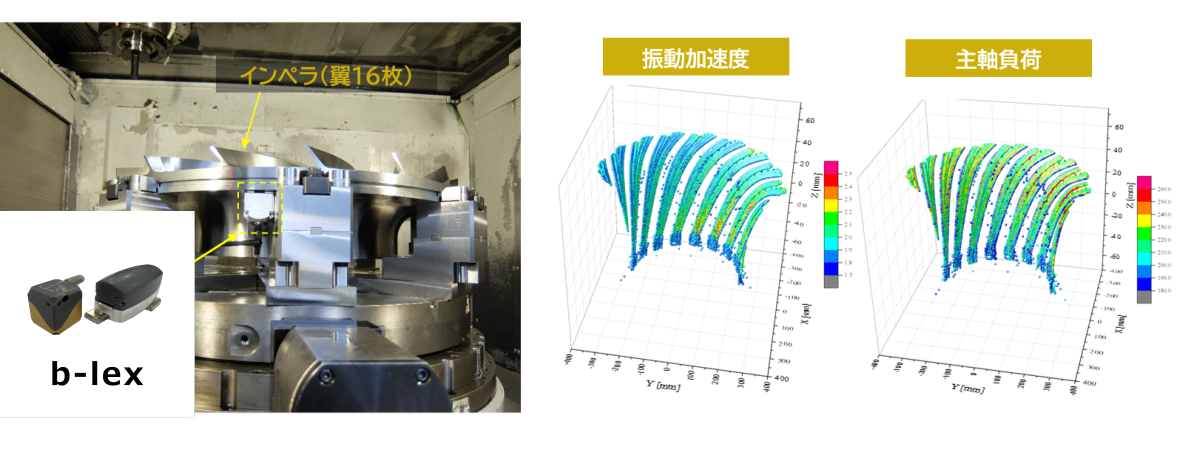

We used b-lex to investigate the change in acceleration accompanying the progression of tool wear.

The tool used was a carbide insert, and the workpiece material was S55C.

It can be seen that there is a correlation between acceleration and cutting resistance.

Finally, a defect occurred at the cutting edge, and it was found that the acceleration and cutting resistance sharply increased at that time.

Since a correlation between acceleration by b-lex and cutting resistance was observed, changes in load during machining could also be evaluated by acceleration.

This enables anomaly detection and tool life prediction during machining.

We solve these kinds of problems

I want to know better conditions

than the current machining conditions

I want to know the machinability of new tools

I want to know the machinability of new materials

I want to know the performance of new cutting fluids

MULTI INTELLIGENCE® Stationary Wireless Acceleration Sensor b-lex is also available for rent.

If you are wondering what it can do, please check the performance of MULTI INTELLIGENCE® through our rental service.

*Please prepare your own PC

We have compiled frequently asked questions from everyone.

We welcome questions other than those listed below, so please feel free to contact us.

This device enables real-time monitoring of tool temperature and vibration during cutting. Temperature measurement while applying coolant is also possible (inner-through possible). Vibration measurement is possible simply by holding the tool.

High-speed sampling of acceleration data enables frequency analysis. (Sampling rate 44.1kHz)

Reads the true waveform through high-speed data collection and supports the selection of optimal machining conditions.