What is a Tool Presetter?

Source: ZOLLER venturion450

A **tool presetter** is an important tool that contributes to the **efficiency** and **quality improvement** of the machining process.

It can accurately measure the dimensions and position of the tools used for machining.

Since tool measurement is performed **outside the machine tool**, the machine tool downtime during setup can be reduced.

Furthermore, tool-related data is stored in a database, allowing for reference to necessary information at any time.

By setting accurate dimensions and positions, the consistency of the product shape and finish is ensured, and the number of defective products can be reduced.

This is expected to lead to **improved production quality** and **reduced defects**.

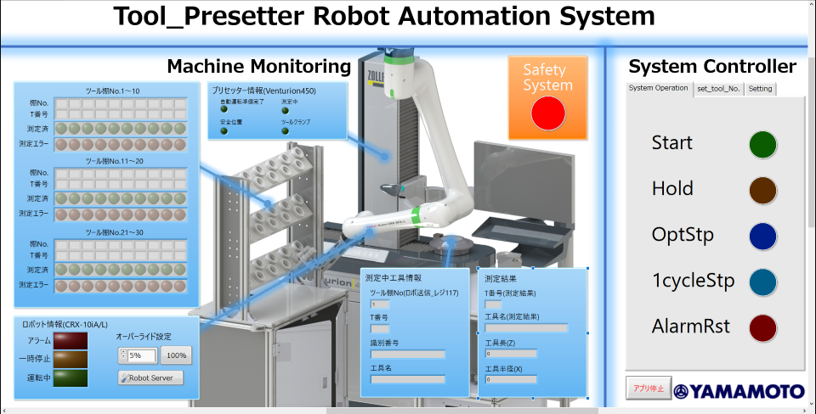

Tool Presetter Automation System

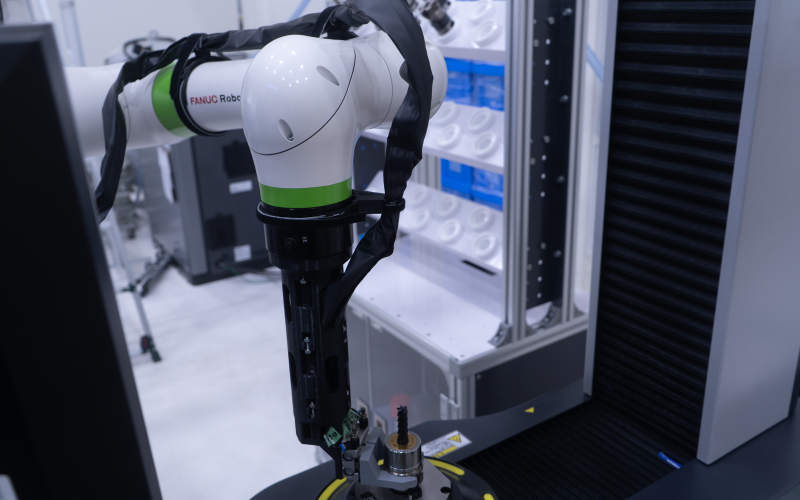

Tool Transfer by Robot

A 6-axis robot transfers tools

to automate tool measurement

Design considering human-collaborative work

Ceiling-mount layout

secures human workspace

Control by dedicated application

Batch control of

robot and tool presetter

Utilizing Yamamoto Kinzoku’s robot SIer technology, we automate ZOLLER’s tool presetter “venturion450”.

The system automatically picks up the tool, installs it into the main unit, measures it, and then transports the tool back to its original position.

The measured tool diameter and tool length of various tools are saved and sent to the machine tool via the application.

This offers benefits such as improved setup efficiency, increased productivity, and enhanced quality.

Robot Main Unit

Uses FANUC Collaborative Robot CRX10iA-L (10kg payload)

The ceiling-mount specification allows human access to the working area

(Height from the floor when the robot arm is folded… approx. 2m)

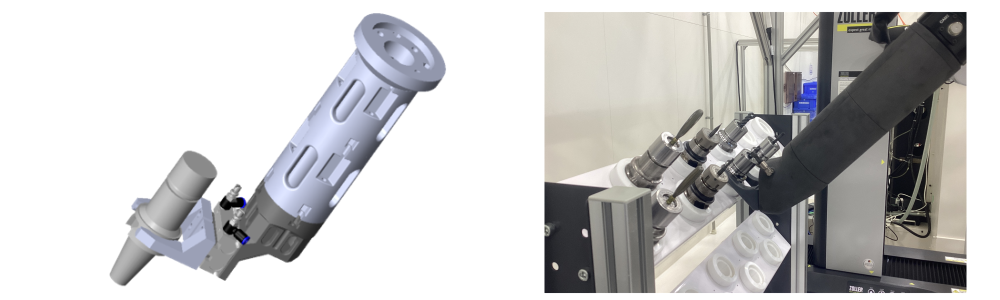

Robot Hand / Arm

The robot hand and robot arm are manufactured in-house

Robot arm components are designed for both strength and light weight, and manufactured using a 3D printer

The gripper part of the hand is also manufactured with a 3D printer so that it can handle various tools simply by replacing the gripper

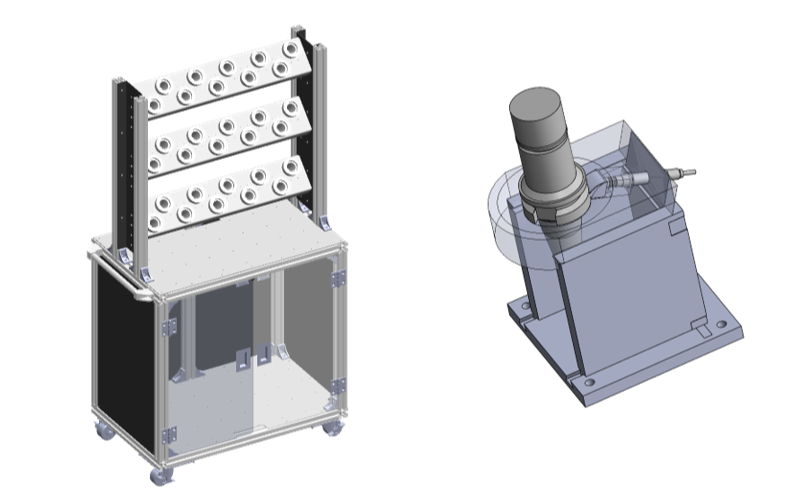

Tool Wagon / Positioning Rotary Table

Uses an in-house manufactured tool wagon

The top half is a tool shelf, and the bottom half has swing doors

It adopts a caster-mobile design, anticipating future AGV integration

Can store a maximum of 10 tools × 3 tiers = 30 tools (BT30 holders)

The positioning rotary table identifies the position of the tool’s drive key,

allowing it to be set into the presetter in a consistent orientation

Control System (PC Application)

Uses an in-house developed control application

It can connect the robot and the tool presetter to perform motion control

It can also connect to a machine tool and automatically generate an NC program that reflects the measured values (tool diameter/tool length)

By transferring the NC program to the machine tool and executing it on the machine side, the tool measurement values are input

venturion450 (Tool Presetter)

The tool presetter used is ZOLLER venturion450

Capable of measurement in 1 μm increments, with a repeatability of ±2 μm

It can perform inspections for wear and chipping, and measure the tool diameter/tool length of various tools (standard function)

Fully automatic measurement is possible through the drive of the CNC-controlled axes (option)

Core height measurement of turning tools is possible (option)

(The above specifications are extracted from the ZOLLER venturion catalog)

Communication with the system control software is performed via TCP/IP communication, enabling the execution of safety position movement, tool clamp/unclamp, and measurement start commands via the control software on the PC from the robot

Flow from Order to Request

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email.

We will respond quickly.

- We will conduct a hearing and ask about your requests

- We will coordinate your requests through a visit or a web conferencing system meeting.

We will submit a quotation based on the requested specifications.

- Our representative, knowledgeable in robots, will visit upon request

- Upon request, our representative will visit your location.

(However, visits may not be possible depending on the region, etc.)

We will propose the best solution for your product.

- TOP

- Business Introduction

- Tool Presetter Automation System