Achieving both reduced operator burden and efficiency! NC Lathe Automation Case using a Collaborative Robot

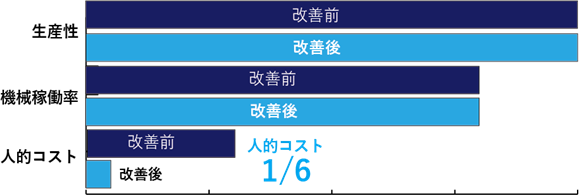

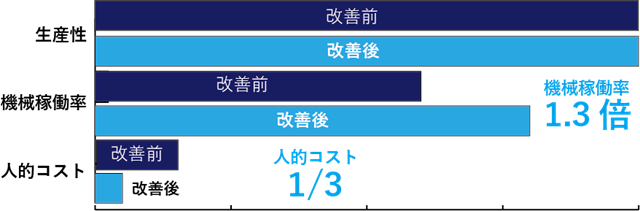

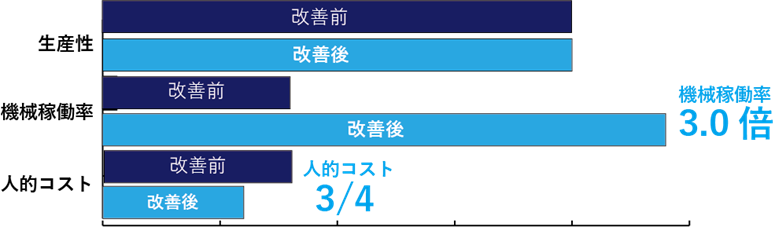

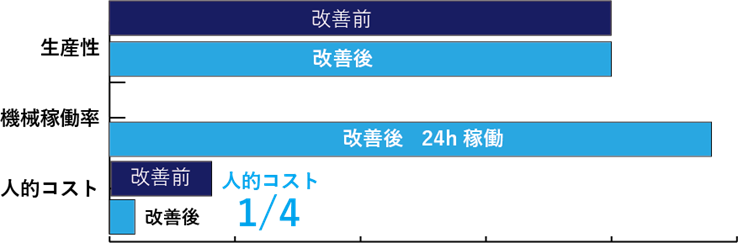

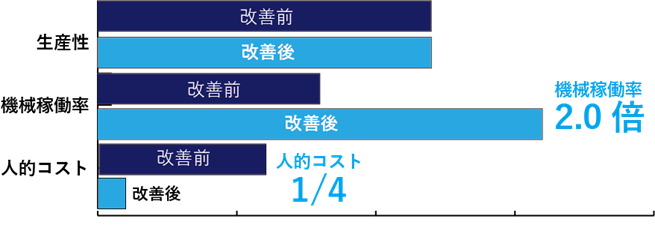

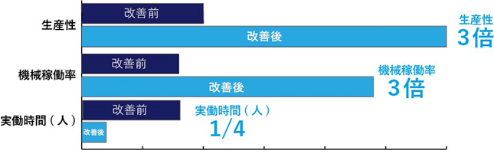

Introduction Effect

- Before

- Picking material from the workpiece shelf

Cleaning with air blow, then chucking to the lathe

Returning to the workpiece shelf after machining is complete

- After

- Setting material on the workpiece shelf

Features

・Flexible switching between human work and robot operation

→Free space in front of the full-surface door

・One robot hand supports two processes

→Hand shape devised

Target Machine

Introduced Machine: NC Lathe Takisawa Machine Tool: TCN2100L6 (Front automatic door)

Introduced Robot: 10kg payload Collaborative Robot