Precision Machining Technology

Since our founding, we have been dedicated to advancing the “technology of cutting, polishing, and drilling metal” and have enhanced our precision machining technology.

We deliver reliable products through a production management system capable of accepting bulk orders, from high-mix low-volume to mass production, and with our extensive machining equipment.

We cater to a wide range of fields, including hydraulic equipment parts, medical device parts, machine tool parts, energy infrastructure parts, semiconductor manufacturing equipment parts, etc.

Examples of Initiatives

Yamamoto Metal Works caters to all industries, possesses a deep understanding of the unique prototype production and part characteristics of each industry, and responds to customer needs with industry-leading precision and speed.

Examples of Compatible Materials

●Iron ●Stainless Steel ●Aluminum ●Copper ●Brass ●Magnesium ●Titanium

●Inconel ●Hastelloy ●Cast Iron ●Resin ●Ceramics ●MMC ●CFRP, etc.

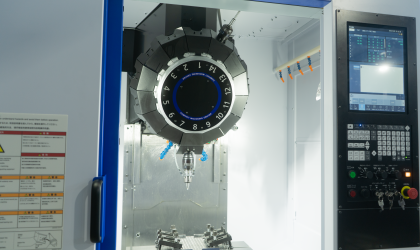

Abundant equipment capable of handling everything from prototype machining to mass production

We possess various equipment such as NC lathes, machining centers, tool grinding machines, EDM machines, 3D printers, robots, etc.

NMV8000,NV5000,NV4000,v56i, etc.

| Machining/Testing Equipment |

NC Lathes (including Multi-tasking Lathes)

Machining Centers (including 5-axis Multi-tasking Machines)

Thread Rolling Machines

Ultrasonic Cleaning Machines

Bender

Crimping Machine / Crimping Work Feeder

Milling Machine

CAM Software

4-station Rotary Bending Fatigue Testing Machine

Bending/Torsion Fatigue Testing Machine

Cylindrical Grinding Machine

EDM Machine

Tool Grinding Machine

3D Printer

Robot

See more details about equipment |

| Inspection Equipment |

Contour Measuring Instrument

Projector

Surface Roughness Tester

Roundness Measuring Instrument

Three-dimensional Measuring Machine

Microscope

Image Dimension Measuring Instrument

Rockwell Hardness Tester |

| Other Processing |

Plating, Painting, Black Oxide Treatment, Blasting, Shot Peening, Heat Treatment, etc. |

Numerous National Certified Engineers on Staff

National qualification holders in Machining, Numerical Control Lathes, Numerical Control Milling Machines, Machining Centers, Milling Machines, Electronic Equipment Assembly, Machine Inspection, Fatigue Testing,

Machine Inspection Work, Penetrant Testing, and other fields are on staff. We deliver high-precision products with reliable skills backed by national certification.

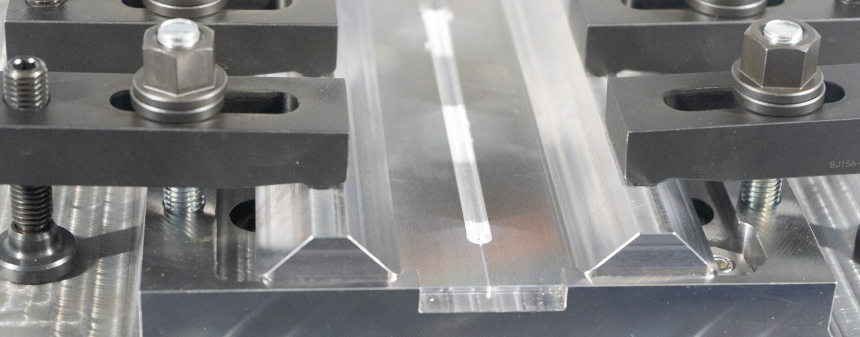

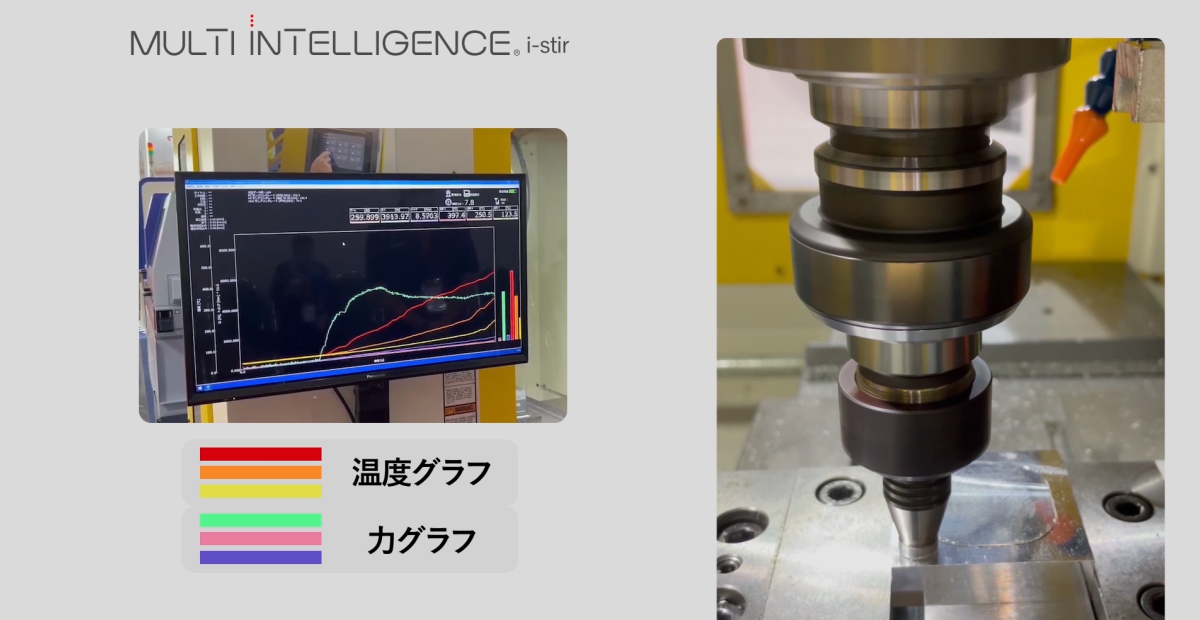

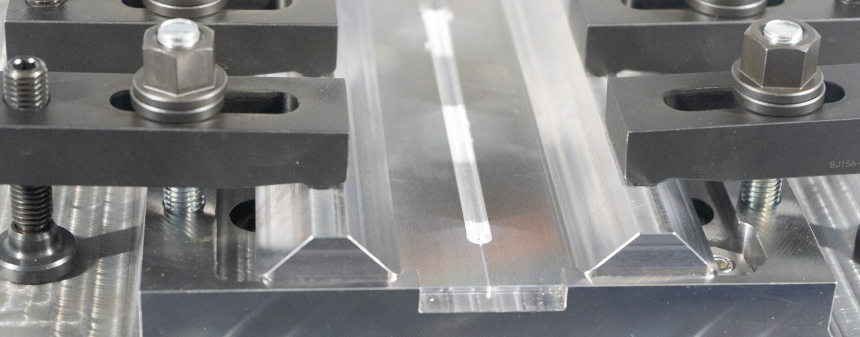

We were quick to focus on FSW (Friction Stir Welding), a new technology, and through accumulated research, we developed MULTI INTELLIGENCE®i-stir and launched services such as FSW Education Support Service, Evaluation Testing Service, and Integration Service. We provide high-quality joining by leveraging this know-how.

Analysis Based on Scientific Knowledge

We provide high-quality products using our know-how in state-of-the-art manufacturing, leveraging our proprietary IoT devices and software like MULTI INTELLIGENCE®, COOL-i®, and Advanced Control®, as well as robots and networks. We specifically introduce MULTI INTELLIGENCE®, which plays a critical role in machining and joining.

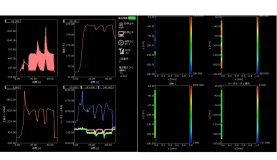

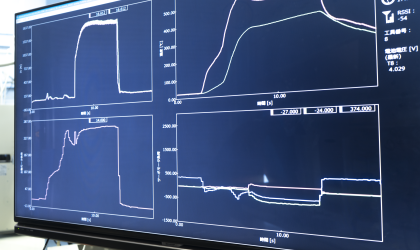

MULTI INTELLIGENCE® enables the acquisition of data during machining and joining.

This also leads to quality assurance through the selection of optimal conditions, anomaly detection, and defect detection.

MULTI INTELLIGENCE®i-stir in action

Furthermore, MULTI INTELLIGENCE® is compatible with BT and HSK holders, allowing it to be used in most machining centers.

Since it allows for cutting with a machining center → joining with MULTI INTELLIGENCE®i-stir, it also reduces man-hours.

Data Analysis of Machining and Joining with MULTI INTELLIGENCE®

EV Related Products

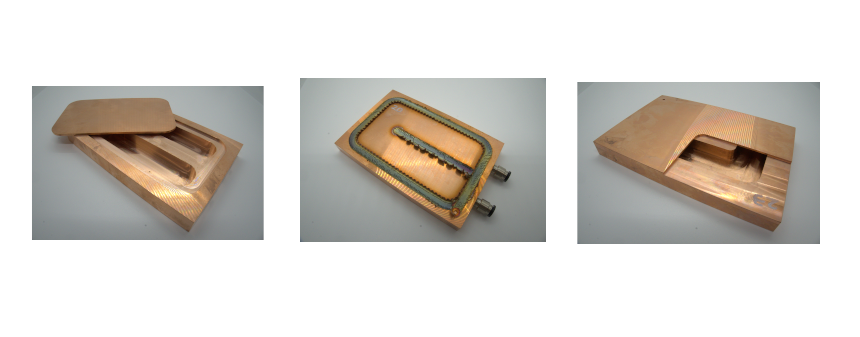

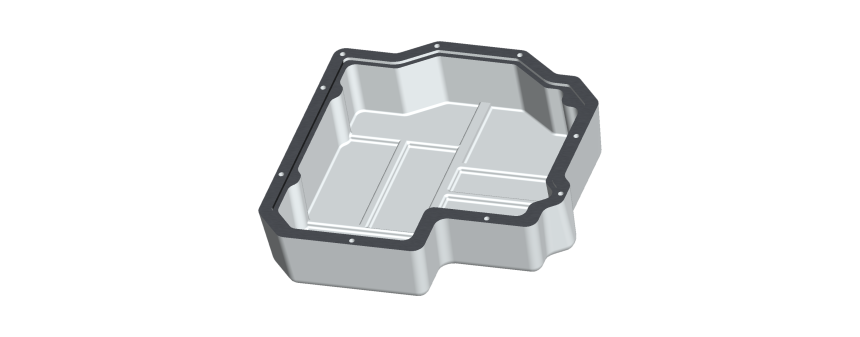

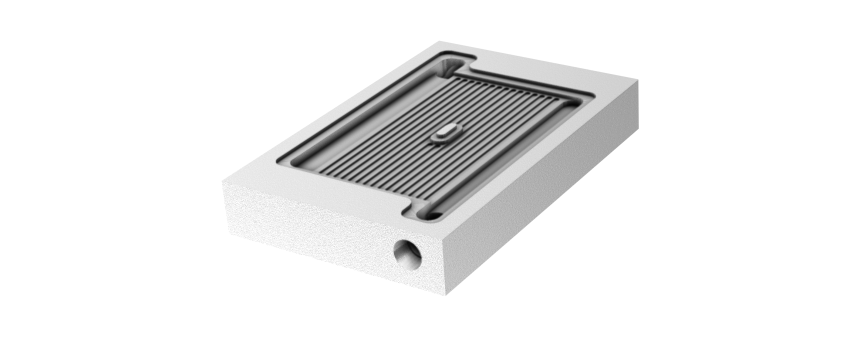

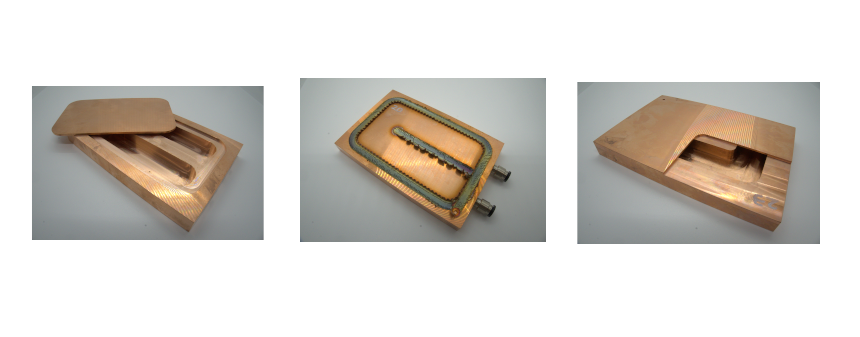

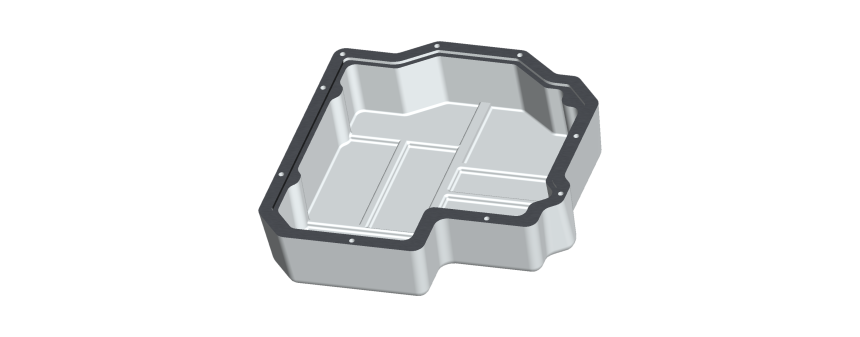

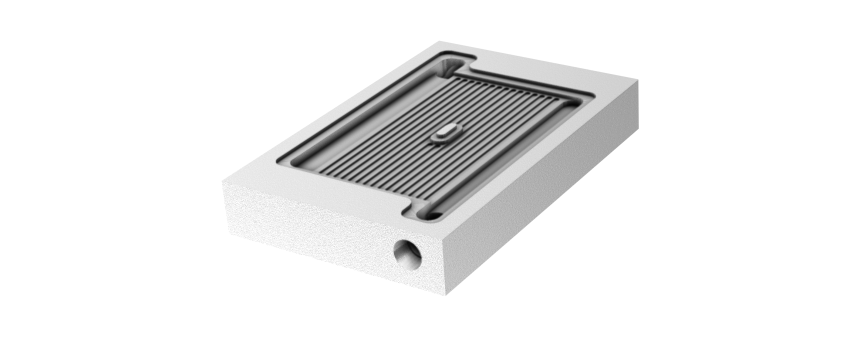

With the shift to EVs in automobiles, FSW is increasingly used for joining body parts due to considerations for weight reduction and heat dissipation. Yamakin manufactures inverter cases (converter cases), battery cases, cooling panels, etc.

*Images are for illustrative purposes only

Cooling Sample (for Data Centers)

Inverter Case (Converter Case)

Battery Case

Cooling Panel

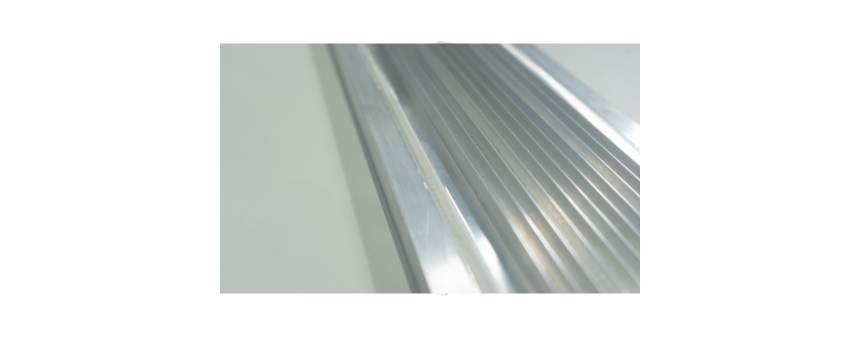

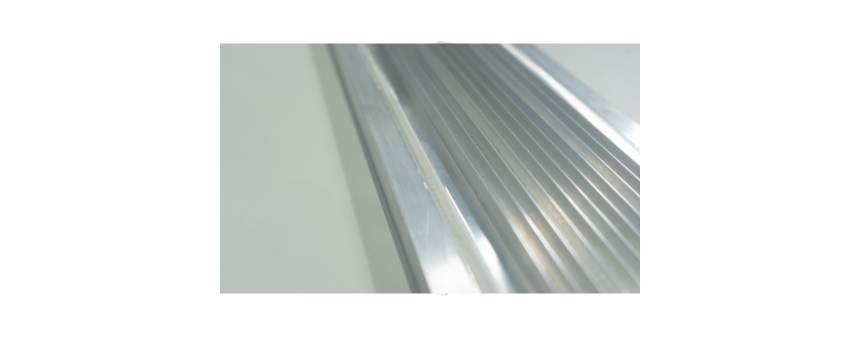

Semiconductor Related

The shape and design of heat sinks vary depending on the equipment and requirements they are used for, but a structure with ribs (vertical fin-like protrusions) or fins is generally common. This increases the surface area and promotes heat exchange with the air. Common applications include use in various electronic devices such as processors, graphics cards, power supplies, and integrated circuits (ICs). FSW enables the manufacture of long heat sinks, which are used in railways, large PCs, and servers.

*Images are for illustrative purposes only

Heat Sink

Flow to ImplementationFlow

- We accept consultations by phone and email

- First, please feel free to contact us by phone or email. We will respond quickly.

step

01

- We will conduct a hearing and ask about your requests

- Please send us your design drawings, and we will listen to your requests in detail.

We will determine if machining and joining are possible, then submit a quote and inform you of the delivery date.

02

- A staff member knowledgeable in machining and joining will visit upon request

- Upon request, our representative will visit your company (however, visits may not be possible depending on the region, etc.).

We will propose solutions that will lead to the best product for your company.

03

- TOP

- Business Introduction

- FSW Machining Business