What is Friction Stir Welding (FSW) ?

Friction Stir Welding (FSW) is a welding technique developed by The Welding Institute Ltd. in 1991.

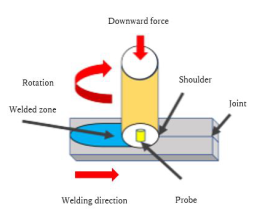

A rotating tool with a central probe is pressed into the joint and traversed along the weld line. Frictional heat, generated mostly under the tool’s shoulder, softens the material. The shoulder also acts to contain the softened material which is forced to the back of the tool, in the process becoming consolidated to form a solid phase weld.

–Courtesy of TWI Ltd–

FSW Tool

FSW Diagram

With many advantages such as no problems with hot cracking, porosity; no filler wire or shielding gas requirement for aluminium alloys, FSW is mostly used to weld aluminium materials in automobile and aerospace industries.

Here is some examples of FSW conducted in our laboratory:

Homogeneous welding

A5083 5t

Heterogeneous welding

Mg Alloy+A6061

In-process temperature monitoring of FSW

Nowadays, with the development of IoT and AI in manufacturing, we find it necessary to “visualize” the real welding condition to prevent some defects may occur.

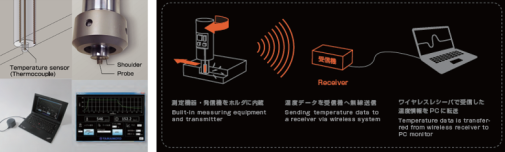

In FSW, the temperature factor plays an important role to make a good weld zone, so we invented an in-process temperature monitoring system called MULTI INTELLIGENCE® that operates with a sensor built in.

Illustration of MULTI INTELLIGENCE® (FSW version) system

Temperatures measured in real time

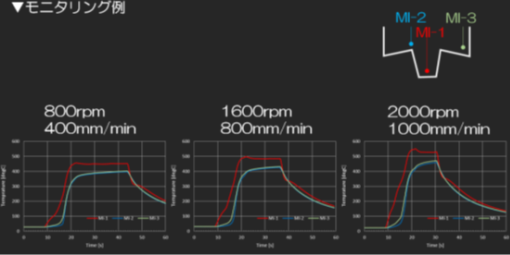

Evalution of FSW condition

The data below shows that even if the input factors (tool rotational speed, traverse speed) are kept unchanged, the temperature of the probe tip will increase significantly once the tool starts touching the welding surface. Then, the temperatures keep almost constant during process.

However, under the condition of 2000rpm, 1000mm/min, we can see an obvious decrease in temperature of the probe tip right after the traverse.

By using an X-ray flaw detector after welding, we found a CAVITY inside welded zone, that is considered to be the reason causing the decrease in temperature.

Example of weld quality evaluation

With specific statistics due to MULTI INTELLIGENCE®, we believe that further research will become possible and the testing results will help improve FSW technology as well as contribute to the development of welding technology.